Page 218 - Electromechanical Devices and Components Illustrated Sourcebook

P. 218

180 Electromechanical Devices & Components Illustrated Sourcebook

the same method as the V-notch unit, except that they have Beryllium Copper

several specific wire size locations in the jaws. These are par- Leaf Spring Terminal

ticularly useful in situations where a technician is working

with several different sizes of wires. Automatic wire strippers

Rotating Hub Electrical Feed

are generally used in production stripping. The wire is placed

into the jaws, a quick squeeze of the handle, and the wire is

stripped and ejected in one quick operation. Thermal wire Axle

strippers are generally used on outer jackets of multiconduc- Machine Frame

tor cables or in applications where it is critical that the con- Figure 10-35 Leaf Spring Rotary Conductor

ductor is not nicked. The jaws are closed onto the insulator,

the plastic is weakened, and the insulation is pulled off. The

temperature of the stripper is adjusted to match the material

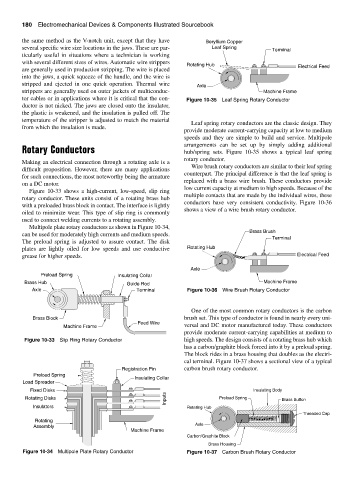

Leaf spring rotary conductors are the classic design. They

from which the insulation is made.

provide moderate current-carrying capacity at low to medium

speeds and they are simple to build and service. Multipole

arrangements can be set up by simply adding additional

Rotary Conductors hub/spring sets. Figure 10-35 shows a typical leaf spring

rotary conductor.

Making an electrical connection through a rotating axle is a

Wire brush rotary conductors are similar to their leaf spring

difficult proposition. However, there are many applications

counterpart. The principal difference is that the leaf spring is

for such connections, the most noteworthy being the armature

replaced with a brass wire brush. These conductors provide

on a DC motor.

low current capacity at medium to high speeds. Because of the

Figure 10-33 shows a high-current, low-speed, slip ring

multiple contacts that are made by the individual wires, these

rotary conductor. These units consist of a rotating brass hub

conductors have very consistent conductivity. Figure 10-36

with a preloaded brass block in contact. The interface is lightly

shows a view of a wire brush rotary conductor.

oiled to minimize wear. This type of slip ring is commonly

used to connect welding currents to a rotating assembly.

Multipole plate rotary conductors as shown in Figure 10-34,

Brass Brush

can be used for moderately high currents and medium speeds.

Terminal

The preload spring is adjusted to assure contact. The disk

plates are lightly oiled for low speeds and use conductive Rotating Hub

grease for higher speeds. Electrical Feed

Axle

Preload Spring Insulating Collar

Brass Hub Guide Rod Machine Frame

Axle Terminal Figure 10-36 Wire Brush Rotary Conductor

One of the most common rotary conductors is the carbon

Brass Block brush set. This type of conductor is found in nearly every uni-

Feed Wire

Machine Frame versal and DC motor manufactured today. These conductors

provide moderate current-carrying capabilities at medium to

Figure 10-33 Slip Ring Rotary Conductor high speeds. The design consists of a rotating brass hub which

has a carbon/graphite block forced into it by a preload spring.

The block rides in a brass housing that doubles as the electri-

cal terminal. Figure 10-37 shows a sectional view of a typical

Registration Pin carbon brush rotary conductor.

Preload Spring

Insulating Collar

Load Spreader

Fixed Disks Insulating Body

Inputs Brass Button

Rotating Disks Preload Spring

Insulators Rotating Hub

Threaded Cap

Rotating

Axle

Assembly

Machine Frame

Carbon/Graphite Block

Brass Housing

Figure 10-34 Multipole Plate Rotary Conductor Figure 10-37 Carbon Brush Rotary Conductor