Page 315 - Electromechanical Devices and Components Illustrated Sourcebook

P. 315

Chapter 16 Electrostatics 277

Corona

5

Insulation Tester 0 1 2 20 30 3 4 40 50 60 70 6 7 8 9 10 Rounded Tip

10 80 90 100

(Megger) 0 Mega Ohms

Sharp Tip

High Low

Leakage Leakage

Insulated

Drive Shaft High High

Component to Be Floated Voltage Voltage

at High Voltage

Figure 16-8 Corona Discharge

Control Panel

Figure 16-7 Verifying High-Voltage Isolation with a Megger

any high voltage that may leak to the panel will be immedi- I turned on the lights, de-energized the circuit and carefully

ately grounded and, therefore, the operator will be protected. applied high-voltage silicone rubber to all of the soldered and

Testing the stand-off voltage capability of a design can be bolted joints. The next morning I re-energized the circuit and

accomplished by using an insulation tester, or megger, as it produced its full 10,000-volt output. The solder and bolted

shown in Figure 16-7. These tests should be carried out only joints were leaking 80% of the power supply’s voltage to air!

while the equipment is de-energized. Additionally, any high- Figure 16-9 shows an example of poor high-voltage solder

voltage isolation system should undergo regularly scheduled joint and the use of high-voltage silicon rubber to suppress

inspections. leakage.

The slow build up of dirt can also produce high-voltage

leaks. This is particularly problematic with equipment that is

forced to operate in dirty and dusty environments. High-

Corona Discharge and High-Voltage performance cabinet filtration will help mitigate the effects of

dirt built-up. Figure 16-10 shows how an exposed stand off

Leaks insulator can be protected from dirt build-up by using a pro-

tective boot. In this case, the leakage would be from the

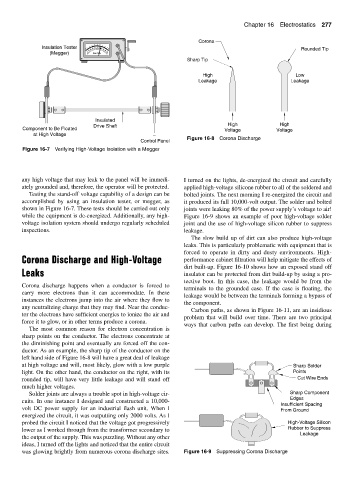

Corona discharge happens when a conductor is forced to

terminals to the grounded case. If the case is floating, the

carry more electrons than it can accommodate. In these

leakage would be between the terminals forming a bypass of

instances the electrons jump into the air where they flow to

the component.

any neutralizing charge that they may find. Near the conduc-

Carbon paths, as shown in Figure 16-11, are an insidious

tor the electrons have sufficient energies to ionize the air and

problem that will build over time. There are two principal

force it to glow, or in other terms produce a corona.

ways that carbon paths can develop. The first being during

The most common reason for electron concentration is

sharp points on the conductor. The electrons concentrate at

the diminishing point and eventually are forced off the con-

ductor. As an example, the sharp tip of the conductor on the

left hand side of Figure 16-8 will have a great deal of leakage

at high voltage and will, most likely, glow with a low purple Sharp Solder

light. On the other hand, the conductor on the right, with its Points

rounded tip, will have very little leakage and will stand off Cut Wire Ends

much higher voltages.

Solder joints are always a trouble spot in high-voltage cir- Sharp Component

Edges

cuits. In one instance I designed and constructed a 10,000-

Insufficient Spacing

volt DC power supply for an industrial flash unit. When I From Ground

energized the circuit, it was outputting only 2000 volts. As I

probed the circuit I noticed that the voltage got progressively High-Voltage Silicon

lower as I worked through from the transformer secondary to Rubber to Suppress

Leakage

the output of the supply. This was puzzling. Without any other

ideas, I turned off the lights and noticed that the entire circuit

was glowing brightly from numerous corona discharge sites. Figure 16-9 Suppressing Corona Discharge