Page 318 - Electromechanical Devices and Components Illustrated Sourcebook

P. 318

280 Electromechanical Devices & Components Illustrated Sourcebook

Electromechanical mechanisms can be extremely complex

assemblies. Consider an automobile, a clothes washer, your

computer printer, or the air conditioner, all are just big elec-

tromechanical components. Door

This chapter of the book is intended to expose the reader to Frame

a few miscellaneous electromechanical components and

Hinge

assemblies that haven’t been reviewed in the previous chapters.

Anchor Block

Strain Relief

Solenoid Door Latch

Cable

Figure 17-1 shows a simple solenoid-activated door latch. The

bolt is spring-loaded and interfaces with a striker, so the sys-

tem will automatically latch when the door is closed. To

unlock the mechanism, the solenoid is energized and the

plunger toggles the link, which, in turn, pulls the bolt back.

Figure 17-2 Hinge Cable

Fracture Groove

Door Swing Head Shank

Nut

Bolt Link

Frame Door Trigger Leads

Connecting Link

Toggle Pivot

Bolt

Charge Head

Toggle Link Striker Explosive Charge

O-Ring

Bolt Frame Mating Surfaces

Fixed Pivot of Flanges

Spring Pin

Return Spring Figure 17-3 Explosive Bolt

Solenoid Pivot

Solenoid

Solenoid Plunger

Figure 17-1 Solenoid Latch

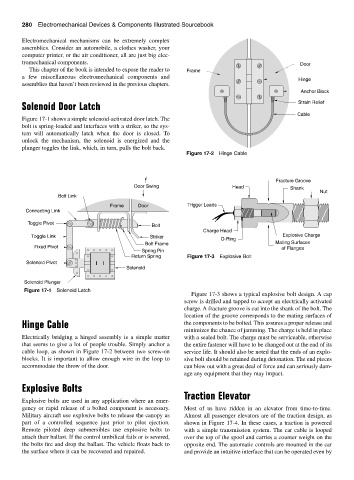

Figure 17-3 shows a typical explosive bolt design. A cap

screw is drilled and tapped to accept an electrically activated

charge. A fracture groove is cut into the shank of the bolt. The

location of the groove corresponds to the mating surfaces of

Hinge Cable the components to be bolted. This assures a proper release and

minimizes the chance of jamming. The charge is held in place

Electrically bridging a hinged assembly is a simple matter with a sealed bolt. The charge must be serviceable, otherwise

that seems to give a lot of people trouble. Simply anchor a the entire fastener will have to be changed out at the end of its

cable loop, as shown in Figure 17-2 between two screw-on service life. It should also be noted that the ends of an explo-

blocks. It is important to allow enough wire in the loop to sive bolt should be retained during detonation. The end pieces

accommodate the throw of the door. can blow out with a great deal of force and can seriously dam-

age any equipment that they may impact.

Explosive Bolts

Traction Elevator

Explosive bolts are used in any application where an emer-

gency or rapid release of a bolted component is necessary. Most of us have ridden in an elevator from time-to-time.

Military aircraft use explosive bolts to release the canopy as Almost all passenger elevators are of the traction design, as

part of a controlled sequence just prior to pilot ejection. shown in Figure 17-4. In these cases, a traction is powered

Remote piloted deep submersibles use explosive bolts to with a simple transmission system. The car cable is looped

attach their ballast. If the control umbilical fails or is severed, over the top of the spool and carries a counter weight on the

the bolts fire and drop the ballast. The vehicle floats back to opposite end. The automatic controls are mounted in the car

the surface where it can be recovered and repaired. and provide an intuitive interface that can be operated even by