Page 322 - Electromechanical Devices and Components Illustrated Sourcebook

P. 322

284 Electromechanical Devices & Components Illustrated Sourcebook

Pointer

Tension Spring Axle

Tuner Pulley Knob

FM 88 90 92 94 96 98 100 102 104 106 108 MHz

AM 540 600 700 800 1000 1200 1400 1600 kHz

Tuner Axle

Idler

Fixed Cable End

Scale

Figure 17-13 String Tuner Drive

When the variable capacitor is replaced with a potentiometer, Pump

Pressure Switch

the scale can indicate voltage, resistance, volume, balance,

and the like. Motor

Motor

Controller

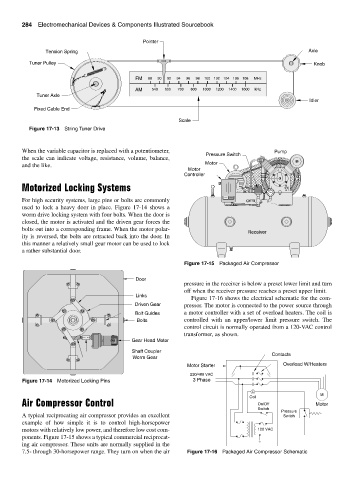

Motorized Locking Systems

For high security systems, large pins or bolts are commonly

used to lock a heavy door in place. Figure 17-14 shows a

worm drive locking system with four bolts. When the door is

closed, the motor is activated and the driven gear forces the

bolts out into a corresponding frame. When the motor polar-

Receiver

ity is reversed, the bolts are retracted back into the door. In

this manner a relatively small gear motor can be used to lock

a rather substantial door.

Figure 17-15 Packaged Air Compressor

Door

pressure in the receiver is below a preset lower limit and turn

off when the receiver pressure reaches a preset upper limit.

Links

Figure 17-16 shows the electrical schematic for the com-

Driven Gear pressor. The motor is connected to the power source through

Bolt Guides a motor controller with a set of overload heaters. The coil is

Bolts controlled with an upper/lower limit pressure switch. The

control circuit is normally operated from a 120-VAC control

transformer, as shown.

Gear Head Motor

Shaft Coupler

Contacts

Worm Gear

Motor Starter Overload W/Heaters

220/480 VAC

Figure 17-14 Motorized Locking Pins 3 Phase

C

M

Coil

Air Compressor Control On/Off Motor

Switch

Pressure

A typical reciprocating air compressor provides an excellent Switch

example of how simple it is to control high-horsepower

motors with relatively low power, and therefore low cost com- 120 VAC

ponents. Figure 17-15 shows a typical commercial reciprocat-

ing air compressor. These units are normally supplied in the

7.5- through 30-horsepower range. They turn on when the air Figure 17-16 Packaged Air Compressor Schematic