Page 320 - Electromechanical Devices and Components Illustrated Sourcebook

P. 320

282 Electromechanical Devices & Components Illustrated Sourcebook

Return Spring Power/Brake

Power/Brake Control

Switch

DC Power

Field Terminals

Link Pivot

Output

Dash Pot Resistive Shaft

Pivot Link Load Dump

Power Shaft

Terminals Coupler

Shunt Wound

DC Motor

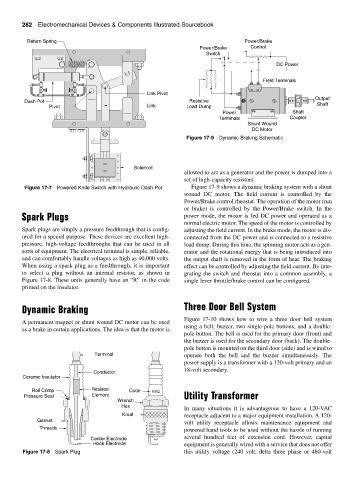

Figure 17-9 Dynamic Braking Schematic

Solenoid

allowed to act as a generator and the power is dumped into a

set of high-capacity resistors.

Figure 17-7 Powered Knife Switch with Hydraulic Dash Pot Figure 17-9 shows a dynamic braking system with a shunt

wound DC motor. The field current is controlled by the

Power/Brake control rheostat. The operation of the motor (run

or brake) is controlled by the Power/Brake switch. In the

Spark Plugs power mode, the motor is fed DC power and operated as a

normal electric motor. The speed of the motor is controlled by

Spark plugs are simply a pressure feedthrough that is config- adjusting the field current. In the brake mode, the motor is dis-

ured for a special purpose. These devices are excellent high- connected from the DC power and is connected to a resistive

pressure, high-voltage feedthroughs that can be used in all load dump. During this time, the spinning motor acts as a gen-

sorts of equipment. The electrical terminal is simple, reliable, erator and the rotational energy that is being introduced into

and can comfortably handle voltages as high as 40,000 volts. the output shaft is removed in the form of heat. The braking

When using a spark plug as a feedthrough, it is important effect can be controlled by adjusting the field current. By inte-

to select a plug without an internal resistor, as shown in grating the switch and rheostat into a common assembly, a

Figure 17-8. These units generally have an “R” in the code single lever throttle/brake control can be configured.

printed on the insulator.

Dynamic Braking Three Door Bell System

Figure 17-10 shows how to wire a three door bell system

A permanent magnet or shunt wound DC motor can be used

using a bell, buzzer, two single-pole buttons, and a double-

as a brake in certain applications. The idea is that the motor is

pole button. The bell is used for the primary door (front) and

the buzzer is used for the secondary door (back). The double-

pole button is mounted on the third door (side) and is wired to

Terminal operate both the bell and the buzzer simultaneously. The

power supply is a transformer with a 120-volt primary and an

18-volt secondary.

Conductor

Ceramic Insulator

Roll Crimp Resistor Code R362

Pressure Seal Element Utility Transformer

Wrench

Hex

In many situations it is advantageous to have a 120-VAC

Knurl receptacle adjacent to a major equipment installation. A 120-

Gasket

volt utility receptacle allows maintenance equipment and

Threads

powered hand tools to be used without the hassle of running

several hundred feet of extension cord. However, capital

Center Electrode

Hook Electrode equipment is generally wired with a service that does not offer

Figure 17-8 Spark Plug this utility voltage (240 volt, delta three phase or 480-volt