Page 50 - Electromechanical Devices and Components Illustrated Sourcebook

P. 50

12 Electromechanical Devices & Components Illustrated Sourcebook

left. Study the illustration carefully and follow the motion of Pulleys

the linkage. Also notice that return springs are applied at both

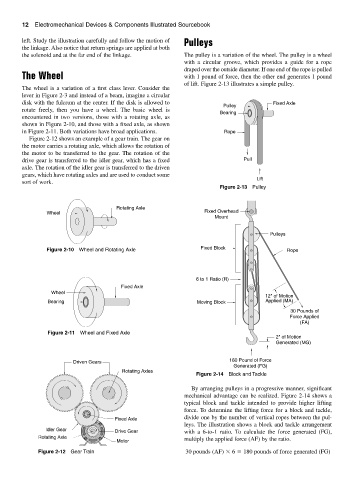

the solenoid and at the far end of the linkage. The pulley is a variation of the wheel. The pulley is a wheel

with a circular groove, which provides a guide for a rope

draped over the outside diameter. If one end of the rope is pulled

The Wheel with 1 pound of force, then the other end generates 1 pound

of lift. Figure 2-13 illustrates a simple pulley.

The wheel is a variation of a first class lever. Consider the

lever in Figure 2-3 and instead of a beam, imagine a circular

disk with the fulcrum at the center. If the disk is allowed to Fixed Axle

Pulley

rotate freely, then you have a wheel. The basic wheel is

Bearing

encountered in two versions, those with a rotating axle, as

shown in Figure 2-10, and those with a fixed axle, as shown

in Figure 2-11. Both variations have broad applications. Rope

Figure 2-12 shows an example of a gear train. The gear on

the motor carries a rotating axle, which allows the rotation of

the motor to be transferred to the gear. The rotation of the

drive gear is transferred to the idler gear, which has a fixed Pull

axle. The rotation of the idler gear is transferred to the driven

gears, which have rotating axles and are used to conduct some

Lift

sort of work.

Figure 2-13 Pulley

Rotating Axle

Wheel Fixed Overhead

Mount

Pulleys

Figure 2-10 Wheel and Rotating Axle Fixed Block Rope

6 to 1 Ratio (R)

Fixed Axle

Wheel

12" of Motion

Bearing Moving Block Applied (MA)

30 Pounds of

Force Applied

(FA)

Figure 2-11 Wheel and Fixed Axle

2" of Motion

Generated (MG)

Driven Gears 180 Pound of Force

Generated (FG)

Rotating Axles

Figure 2-14 Block and Tackle

By arranging pulleys in a progressive manner, significant

mechanical advantage can be realized. Figure 2-14 shows a

typical block and tackle intended to provide higher lifting

force. To determine the lifting force for a block and tackle,

divide one by the number of vertical ropes between the pul-

Fixed Axle

leys. The illustration shows a block and tackle arrangement

Idler Gear Drive Gear with a 6-to-1 ratio. To calculate the force generated (FG),

Rotating Axle multiply the applied force (AF) by the ratio.

Motor

Figure 2-12 Gear Train 30 pounds (AF) 6 180 pounds of force generated (FG)