Page 51 - Electromechanical Devices and Components Illustrated Sourcebook

P. 51

Chapter 2 Basic Mechanics 13

2" Travel 1" Pull

Motor

Two Stage

Vee Belt drive

Fixed Pivot Traction Spool

Solenoid

Pulley

Cable

Counter Weight

Figure 2-15 Doubling Solenoid Throw

Cable

To calculate the motion generated (MG), divide the motion

applied (MA) by the ratio. Load (Elevator)

12" (MA) 6 2" (MG)

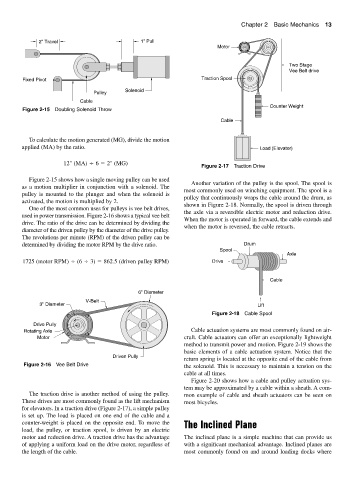

Figure 2-17 Traction Drive

Figure 2-15 shows how a single moving pulley can be used

Another variation of the pulley is the spool. The spool is

as a motion multiplier in conjunction with a solenoid. The

most commonly used on winching equipment. The spool is a

pulley is mounted to the plunger and when the solenoid is

pulley that continuously wraps the cable around the drum, as

activated, the motion is multiplied by 2.

shown in Figure 2-18. Normally, the spool is driven through

One of the most common uses for pulleys is vee belt drives,

the axle via a reversible electric motor and reduction drive.

used in power transmission. Figure 2-16 shows a typical vee belt

When the motor is operated in forward, the cable extends and

drive. The ratio of the drive can be determined by dividing the

when the motor is reversed, the cable retracts.

diameter of the driven pulley by the diameter of the drive pulley.

The revolutions per minute (RPM) of the driven pulley can be

determined by dividing the motor RPM by the drive ratio. Drum

Spool

Axle

1725 (motor RPM) (6 3) 862.5 (driven pulley RPM) Drive

Cable

6" Diameter

V-Belt

3" Diameter Lift

Figure 2-18 Cable Spool

Drive Pully

Rotating Axle Cable actuation systems are most commonly found on air-

Motor craft. Cable actuators can offer an exceptionally lightweight

method to transmit power and motion. Figure 2-19 shows the

basic elements of a cable actuation system. Notice that the

Driven Pully

return spring is located at the opposite end of the cable from

Figure 2-16 Vee Belt Drive the solenoid. This is necessary to maintain a tension on the

cable at all times.

Figure 2-20 shows how a cable and pulley actuation sys-

tem may be approximated by a cable within a sheath. A com-

The traction drive is another method of using the pulley. mon example of cable and sheath actuators can be seen on

These drives are most commonly found as the lift mechanism most bicycles.

for elevators. In a traction drive (Figure 2-17), a simple pulley

is set up. The load is placed on one end of the cable and a

counter-weight is placed on the opposite end. To move the The Inclined Plane

load, the pulley, or traction spool, is driven by an electric

motor and reduction drive. A traction drive has the advantage The inclined plane is a simple machine that can provide us

of applying a uniform load on the drive motor, regardless of with a significant mechanical advantage. Inclined planes are

the length of the cable. most commonly found on and around loading docks where