Page 49 - Electromechanical Devices and Components Illustrated Sourcebook

P. 49

Chapter 2 Basic Mechanics 11

1 Pound of Force Connecting Rod

Applied (FA)

Total Beam Length (L)

3 Pounds of Force Generated (FG)

First Class

2/3 of the Beam Length 1/3 (X) Lever

Fixed Pivot Fixed Pivot

12" of Motion

Applied (MA)

4" of Motion Fulcrum Figure 2-7 Levers and Connecting Rods

Generated (MG)

Beam

Figure 2-5 Second Class Lever

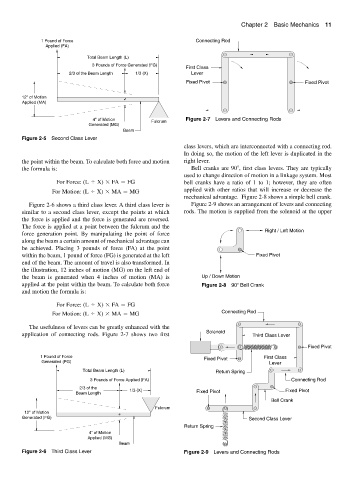

class levers, which are interconnected with a connecting rod.

In doing so, the motion of the left lever is duplicated in the

the point within the beam. To calculate both force and motion right lever.

the formula is: Bell cranks are 90 , first class levers. They are typically

used to change direction of motion in a linkage system. Most

For Force: (L X) FA FG bell cranks have a ratio of 1 to 1; however, they are often

For Motion: (L X) MA MG applied with other ratios that will increase or decrease the

mechanical advantage. Figure 2-8 shows a simple bell crank.

Figure 2-6 shows a third class lever. A third class lever is Figure 2-9 shows an arrangement of levers and connecting

similar to a second class lever, except the points at which rods. The motion is supplied from the solenoid at the upper

the force is applied and the force is generated are reversed.

The force is applied at a point between the fulcrum and the

Right / Left Motion

force generation point. By manipulating the point of force

along the beam a certain amount of mechanical advantage can

be achieved. Placing 3 pounds of force (FA) at the point

within the beam, 1 pound of force (FG) is generated at the left Fixed Pivot

end of the beam. The amount of travel is also transformed. In

the illustration, 12 inches of motion (MG) on the left end of

the beam is generated when 4 inches of motion (MA) is Up / Down Motion

applied at the point within the beam. To calculate both force Figure 2-8 90 Bell Crank

and motion the formula is:

For Force: (L X) FA FG

For Motion: (L X) MA MG Connecting Rod

The usefulness of levers can be greatly enhanced with the

application of connecting rods. Figure 2-7 shows two first Solenoid Third Class Lever

Fixed Pivot

1 Pound of Force First Class

Fixed Pivot

Generated (FG) Lever

Total Beam Length (L) Return Spring

3 Pounds of Force Applied (FA) Connecting Rod

2/3 of the

Beam Length 1/3 (X) Fixed Pivot Fixed Pivot

Bell Crank

Fulcrum

12" of Motion

Generated (FG) Second Class Lever

Return Spring

4" of Motion

Applied (MG)

Beam

Figure 2-6 Third Class Lever Figure 2-9 Levers and Connecting Rods