Page 88 - Electromechanical Devices and Components Illustrated Sourcebook

P. 88

50 Electromechanical Devices & Components Illustrated Sourcebook

Harsh environments, such as the plant floor, require espe-

Actuators

cially rugged limit switches. These units are generally

referred to as industrial limit switches. They generally have

high-impact housings which are impervious to oil, water, and

many chemicals. Figure 4-44 shows two industrial limit

switches, with a center-loaded lever arm and one with latch-

ing lever arms.

For precise control of mechanical movement, a micrometer-

adjustable limit switch may be configured, as shown in

Figure 4-45. This arrangement provides control of the switch Individual

down to 0.001inch. Micrometer adjustable limit switches are Limit Switches

commonly found in modern machine tools. Through Bolts

Figure 4-46 Ganged Limit Switches

OP 30° OP 30°

60° Max. 60° Max.

Travel Travel

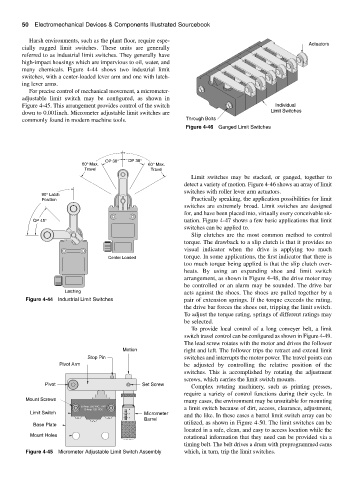

Limit switches may be stacked, or ganged, together to

detect a variety of motion. Figure 4-46 shows an array of limit

switches with roller lever arm actuators.

90° Latch

Position Practically speaking, the application possibilities for limit

switches are extremely broad. Limit switches are designed

for, and have been placed into, virtually every conceivable sit-

OP 45° uation. Figure 4-47 shows a few basic applications that limit

switches can be applied to.

Slip clutches are the most common method to control

torque. The drawback to a slip clutch is that it provides no

visual indicator when the drive is applying too much

Center Loaded torque. In some applications, the first indicator that there is

too much torque being applied is that the slip clutch over-

heats. By using an expanding shoe and limit switch

arrangement, as shown in Figure 4-48, the drive motor may

be controlled or an alarm may be sounded. The drive bar

Latching acts against the shoes. The shoes are pulled together by a

Figure 4-44 Industrial Limit Switches pair of extension springs. If the torque exceeds the rating,

the drive bar forces the shoes out, tripping the limit switch.

To adjust the torque rating, springs of different ratings may

be selected.

To provide local control of a long conveyer belt, a limit

switch travel control can be configured as shown in Figure 4-49.

The lead screw rotates with the motor and drives the follower

Motion right and left. The follower trips the retract and extend limit

Stop Pin switches and interrupts the motor power. The travel points can

Pivot Arm be adjusted by controlling the relative position of the

switches. This is accomplished by rotating the adjustment

screws, which carries the limit switch mounts.

Pivot Set Screw

Complex rotating machinery, such as printing presses,

require a variety of control functions during their cycle. In

Mount Screws many cases, the environment may be unsuitable for mounting

20 Amp. 220 VAC, 1 HP

10 Amp. 120 VDC 0 a limit switch because of dirt, access, clearance, adjustment,

Limit Switch .1 Micrometer

Barrel

.2 and the like. In these cases a barrel limit switch array can be

Base Plate utilized, as shown in Figure 4-50. The limit switches can be

located in a safe, clean, and easy to access location while the

Mount Holes rotational information that they need can be provided via a

timing belt. The belt drives a drum with preprogrammed cams

Figure 4-45 Micrometer Adjustable Limit Switch Assembly which, in turn, trip the limit switches.