Page 184 - Academic Press Encyclopedia of Physical Science and Technology 3rd BioTechnology

P. 184

P1: FMX Final Pages

Encyclopedia of Physical Science and Technology EN009J-69 July 19, 2001 22:50

684 Microanalytical Assays

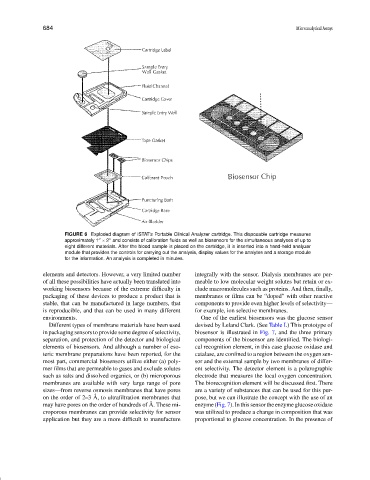

FIGURE 6 Exploded diagram of iSTAT’s Portable Clinical Analyzer cartridge. This disposable cartridge measures

approximately 1 × 2 and consists of calibration fluids as well as biosensors for the simultaneous analyses of up to

eight different materials. After the blood sample is placed on the cartridge, it is inserted into a hand-held analyzer

module that provides the controls for carrying out the analysis, display values for the analytes and a storage module

for the information. An analysis is completed in minutes.

elements and detectors. However, a very limited number integrally with the sensor. Dialysis membranes are per-

of all these possibilities have actually been translated into meable to low molecular weight solutes but retain or ex-

working biosensors because of the extreme difficulty in clude macromolecules such as proteins. And then, finally,

packaging of these devices to produce a product that is membranes or films can be “doped” with other reactive

stable, that can be manufactured in large numbers, that components to provide even higher levels of selectivity—

is reproducible, and that can be used in many different for example, ion selective membranes.

environments. One of the earliest biosensors was the glucose sensor

Different types of membrane materials have been used devised by Leland Clark. (See Table I.) This prototype of

in packaging sensors to provide some degree of selectivity, biosensor is illustrated in Fig. 7, and the three primary

separation, and protection of the detector and biological components of the biosensor are identified. The biologi-

elements of biosensors. And although a number of eso- cal recognition element, in this case glucose oxidase and

teric membrane preparations have been reported, for the catalase, are confined to a region between the oxygen sen-

most part, commercial biosensors utilize either (a) poly- sor and the external sample by two membranes of differ-

mer films that are permeable to gases and exclude solutes ent selectivity. The detector element is a polarographic

such as salts and dissolved organics, or (b) microporous electrode that measures the local oxygen concentration.

membranes are available with very large range of pore The biorecognition element will be discussed first. There

sizes—from reverse osmosis membranes that have pores are a variety of substances that can be used for this pur-

˚

on the order of 2–3 A, to ultrafiltration membranes that pose, but we can illustrate the concept with the use of an

˚

may have pores on the order of hundreds of A. These mi- enzyme (Fig. 7). In this sensor the enzyme glucose oxidase

croporous membranes can provide selectivity for sensor was utilized to produce a change in composition that was

application but they are a more difficult to manufacture proportional to glucose concentration. In the presence of