Page 272 - Academic Press Encyclopedia of Physical Science and Technology 3rd BioTechnology

P. 272

P1: GPB/GRB P2: GLQ Final pages

Encyclopedia of Physical Science and Technology EN016J-783 August 1, 2001 10:58

Tissue Engineering 823

The design of more sophisticated cultured tissues us-

ing more than one cell type can be enhanced by spatially

controlling the seeding process. For this purpose, various

methods for patterning the deposition of extracellular ma-

trix or other cell attachment factors onto surfaces have

been developed. Photolithography involves spin-coating

a surface (typically silicon or glass) with an ∼1-µm thick

layer of photoresist material, exposing the coated material

to ultraviolet light through a mask containing the pattern

of interest, and treating the surface with a developer so-

lution which dissolves the exposed regions of photoresist

only (Fig. 1). This process leaves photoresist in previ-

ously unexposed areas of the substrate. The exposed areas

of substrate can be chemically modified for attaching pro-

teins, etc., or can be treated with hydrofluoric acid to etch

the material. The etching time controls the depth of the

channels created. Subsequently, the leftover photoresist is

removed using an appropriate solvent, which leaves a sur-

face patterned with different molecules and/or grooves.

A disadvantage of this method is that it uses chemicals

toxic to cells and generally harsh conditions which could

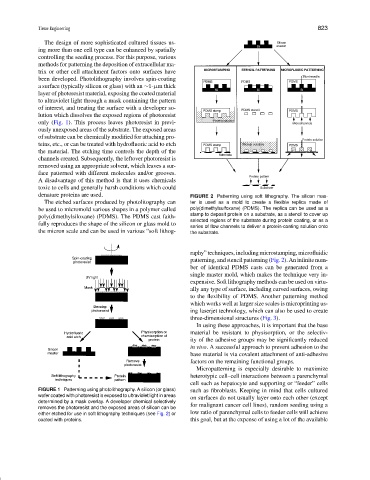

denature proteins are used. FIGURE 2 Patterning using soft lithography. The silicon mas-

The etched surfaces produced by photolitography can ter is used as a mold to create a flexible replica made of

be used to micromold various shapes in a polymer called poly(dimethylsulfoxane) (PDMS). The replica can be used as a

poly(dimethylsiloxane) (PDMS). The PDMS cast faith- stamp to deposit protein on a substrate, as a stencil to cover up

selected regions of the substrate during protein coating, or as a

fully reproduces the shape of the silicon or glass mold to

series of flow channels to deliver a protein-coating solution onto

the micron scale and can be used in various “soft lithog- the substrate.

raphy” techniques, including microstamping, microfluidic

patterning, and stencil patterning (Fig. 2). An infinite num-

ber of identical PDMS casts can be generated from a

single master mold, which makes the technique very in-

expensive. Soft lithography methods can be used on virtu-

ally any type of surface, including curved surfaces, owing

to the flexibility of PDMS. Another patterning method

which works well at larger size scales is microprinting us-

ing laserjet technology, which can also be used to create

three-dimensional structures (Fig. 3).

In using these approaches, it is important that the base

material be resistant to physisorption, or the selectiv-

ity of the adhesive groups may be significantly reduced

in vivo. A successful approach to prevent adhesion to the

base material is via covalent attachment of anti-adhesive

factors on the remaining functional groups.

Micropatterning is especially desirable to maximize

heterotypic cell–cell interactions between a parenchymal

cell such as hepatocyte and supporting or “feeder” cells

FIGURE 1 Patterning using photolithography. A silicon (or glass) such as fibroblasts. Keeping in mind that cells cultured

wafer coated with photoresist is exposed to ultraviolet light in areas on surfaces do not usually layer onto each other (except

determined by a mask overlay. A developer chemical selectively

removes the photoresist and the exposed areas of silicon can be for malignant cancer cell lines), random seeding using a

either etched for use in soft lithography techniques (see Fig. 2) or low ratio of parenchymal cells to feeder cells will achieve

coated with proteins. this goal, but at the expense of using a lot of the available