Page 82 - Academic Press Encyclopedia of Physical Science and Technology 3rd BioTechnology

P. 82

P1: GRB Final Pages

Encyclopedia of Physical Science and Technology EN002G-67 May 25, 2001 20:8

264 Bioreactors

clean-in-placemethods.In-placecleaningdoesnotrequire

dismantling the bioreactor and saves time. Automation as-

sures consistency of cleaning. Cleaning between batches

is essential to preventing cross-contamination of products.

Also, a clean bioreactor is easier to sterilize. Cleaning

is achieved by physical action of high velocity flow, jet

sprays, agitation, and chemical action of cleaning agents

enhanced by heat. While mechanical forces are necessary

to remove gross soil and to ensure adequate penetration

of cleaning solutions to all areas, most of the cleaning ac-

tion is provided by chemicals—surfactants, acids, alkalis,

and sanitizers. A generally applicable cleaning scheme for

bioreactors utilizes a water pre-rinse to remove gross soil;

a hot alkali recirculation step to digest and dissolve away

the remaining soil; and a water wash to remove residual

alkali. A bioreactor that processes injectable drugs, should

be rinsed with a hot water-for-injection (WFI) wash as the

final cleaning step. Optional acid wash and sanitization

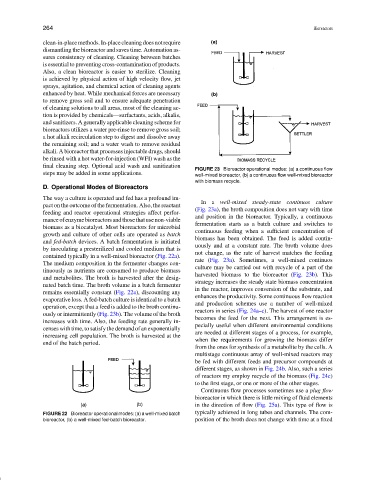

FIGURE 23 Bioreactor operational modes: (a) a continuous flow

steps may be added in some applications. well-mixed bioreactor, (b) a continuous flow well-mixed bioreactor

with biomass recycle.

D. Operational Modes of Bioreactors

The way a culture is operated and fed has a profound im-

In a well-mixed steady-state continuos culture

pact on the outcome of the fermentation. Also, the reactant

(Fig. 23a), the broth composition does not vary with time

feeding and reactor operational strategies affect perfor-

and position in the bioreactor. Typically, a continuous

manceofenzymebioreactorsandthosethatusenon-viable

fermentation starts as a batch culture and switches to

biomass as a biocatalyst. Most bioreactors for microbial

continuous feeding when a sufficient concentration of

growth and culture of other cells are operated as batch

biomass has been obtained. The feed is added contin-

and fed-batch devices. A batch fermentation is initiated

uously and at a constant rate. The broth volume does

by inoculating a presterilized and cooled medium that is

not change, as the rate of harvest matches the feeding

contained typically in a well-mixed bioreactor (Fig. 22a).

rate (Fig. 23a). Sometimes, a well-mixed continuos

The medium composition in the fermenter changes con-

culture may be carried out with recycle of a part of the

tinuously as nutrients are consumed to produce biomass

harvested biomass to the bioreactor (Fig. 23b). This

and metabolites. The broth is harvested after the desig-

strategy increases the steady state biomass concentration

nated batch time. The broth volume in a batch fermenter

in the reactor, improves conversion of the substrate, and

remains essentially constant (Fig. 22a), discounting any

enhances the productivity. Some continuous flow reaction

evaporative loss. A fed-batch culture is identical to a batch

and production schemes use a number of well-mixed

operation, except that a feed is added to the broth continu-

reactors in series (Fig. 24a–c). The harvest of one reactor

ously or intermittently (Fig. 23b). The volume of the broth

becomes the feed for the next. This arrangement is es-

increases with time. Also, the feeding rate generally in-

pecially useful when different environmental conditions

censes with time, to satisfy the demand of an exponentially

are needed at different stages of a process, for example,

increasing cell population. The broth is harvested at the

when the requirements for growing the biomass differ

end of the batch period.

from the ones for synthesis of a metabolite by the cells. A

multistage continuous array of well-mixed reactors may

be fed with different feeds and precursor compounds at

different stages, as shown in Fig. 24b. Also, such a series

of reactors my employ recycle of the biomass (Fig. 24c)

to the first stage, or one or more of the other stages.

Continuous flow processes sometimes use a plug flow

bioreactor in which there is little mixing of fluid elements

in the direction of flow (Fig. 25a). This type of flow is

FIGURE 22 Bioreactor operational modes: (a) a well-mixed batch typically achieved in long tubes and channels. The com-

bioreactor, (b) a well-mixed fed-batch bioreactor. position of the broth does not change with time at a fixed