Page 22 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 22

P1: LDK Revised Pages

Encyclopedia of Physical Science and Technology EN001H-01 May 7, 2001 16:18

Absorption (Chemical Engineering) 19

caused by massive liquid carryover from tray to tray (en-

trainment flood) or when liquid backup in the downcomer

reaches the tray above (downcomer backup flood) or when

the downcomer is unable to handle the total quantity of

descending liquid (downcomer choke flood). At low liq-

uid rates and high gas velocities, entrainment flooding is

the most common limit. At high liquid flow rates and low

gas velocities (e.g., high pressure operation), downcomer

backup and downcomer choke flood are the most common

limits.

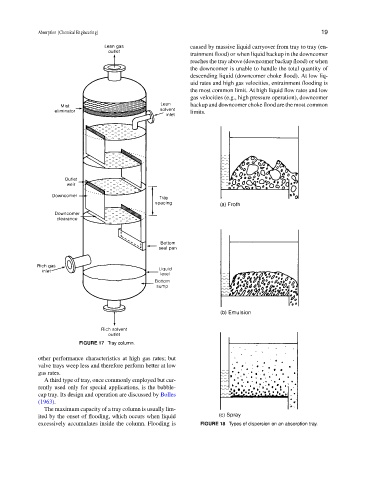

FIGURE 17 Tray column.

other performance characteristics at high gas rates; but

valve trays weep less and therefore perform better at low

gas rates.

A third type of tray, once commonly employed but cur-

rently used only for special applications, is the bubble-

cap tray. Its design and operation are discussed by Bolles

(1963).

The maximum capacity of a tray column is usually lim-

ited by the onset of flooding, which occurs when liquid

excessively accumulates inside the column. Flooding is FIGURE 18 Types of dispersion on an absorption tray.