Page 225 - Academic Press Encyclopedia of Physical Science and Technology 3rd Chemical Engineering

P. 225

P1: GJC Final Pages

Encyclopedia of Physical Science and Technology EN004E-182 June 8, 2001 18:16

Distillation 549

nents, encounters upflowing vapor, which is not as rich

in these components, the difference in composition, or

lack of equilibrium between the two phases, causes high-

volatility components to transfer from the liquid to the

vapor and low-volatility components to transfer from the

vapor to the liquid. The upflowing vapor is made richer in

high-volatility components and vice versa for the liquid.

Refluxing improves the separation that is achieved in

most distillation columns. Any reflux rate increase, how-

ever, requires an increase in the rate of vapor production at

the bottom of the column and hence an increase in energy

consumption.

Contrary to the implication of Fig. 2, the condenser is

usually not located at the top of the column and instead

is often located some 3 to 6 m above the ground on a

permanent scaffold or platform. The reflux drum is located

beneath the condenser. A pump sends the reflux liquid to

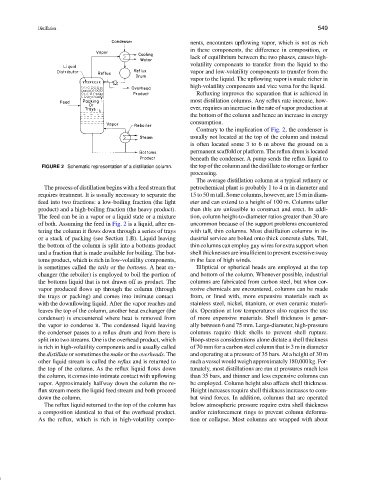

FIGURE 2 Schematic representation of a distillation column. the top of the column and the distillate to storage or further

processing.

The average distillation column at a typical refinery or

The process of distillation begins with a feed stream that petrochemical plant is probably 1 to4min diameter and

requires treatment. It is usually necessary to separate the 15 to 50 m tall. Some columns, however, are 15 m in diam-

feed into two fractions: a low-boiling fraction (the light eter and can extend to a height of 100 m. Columns taller

product) and a high-boiling fraction (the heavy product). than this are unfeasible to construct and erect. In addi-

The feed can be in a vapor or a liquid state or a mixture tion, column height-to-diameter ratios greater than 30 are

of both. Assuming the feed in Fig. 2 is a liquid, after en- uncommon because of the support problems encountered

tering the column it flows down through a series of trays with tall, thin columns. Most distillation columns in in-

or a stack of packing (see Section 1.B). Liquid leaving dustrial service are bolted onto thick concrete slabs. Tall,

the bottom of the column is split into a bottoms product thin columns can employ guy wires for extra support when

and a fraction that is made available for boiling. The bot- shell thicknesses are insufficient to prevent excessive sway

toms product, which is rich in low-volatility components, in the face of high winds.

is sometimes called the tails or the bottoms. A heat ex- Elliptical or spherical heads are employed at the top

changer (the reboiler) is employed to boil the portion of and bottom of the column. Whenever possible, industrial

the bottoms liquid that is not drawn off as product. The columns are fabricated from carbon steel, but when cor-

vapor produced flows up through the column (through rosive chemicals are encountered, columns can be made

the trays or packing) and comes into intimate contact from, or lined with, more expensive materials such as

with the downflowing liquid. After the vapor reaches and stainless steel, nickel, titanium, or even ceramic materi-

leaves the top of the column, another heat exchanger (the als. Operation at low temperatures also requires the use

condenser) is encountered where heat is removed from of more expensive materials. Shell thickness is gener-

the vapor to condense it. The condensed liquid leaving ally between 6 and 75 mm. Large-diameter, high-pressure

the condenser passes to a reflux drum and from there is columns require thick shells to prevent shell rupture.

split into two streams. One is the overhead product, which Hoop-stress considerations alone dictate a shell thickness

is rich in high-volatility components and is usually called of 70 mm for a carbon steel column that is 3 m in diameter

the distillate or sometimes the make or the overheads. The and operating at a pressure of 35 bars. At a height of 30 m

other liquid stream is called the reflux and is returned to suchavesselwouldweighapproximately180,000kg.For-

the top of the column. As the reflux liquid flows down tunately, most distillations are run at pressures much less

the column, it comes into intimate contact with upflowing than 35 bars, and thinner and less expensive columns can

vapor. Approximately halfway down the column the re- be employed. Column height also affects shell thickness.

flux stream meets the liquid feed stream and both proceed Height increases require shell thickness increases to com-

down the column. bat wind forces. In addition, columns that are operated

The reflux liquid returned to the top of the column has below atmospheric pressure require extra shell thickness

a composition identical to that of the overhead product. and/or reinforcement rings to prevent column deforma-

As the reflux, which is rich in high-volatility compo- tion or collapse. Most columns are wrapped with about