Page 136 - Academic Press Encyclopedia of Physical Science and Technology 3rd Polymer

P. 136

P1: FMX/LSU P2: GPB/GRD P3: GLQ Final pages

Encyclopedia of Physical Science and Technology EN012c-593 July 26, 2001 15:56

642 Polymer Processing

The process of inflating the parison is primarily one

of planar extensional flow especially away from the ends

of the parsion. Because the ends of the parsion are con-

strained as the parison expands, the thickness of the wall

decreases as the diameter expands leading to primarily

planar extensional deformation. For this reason the blow

molded part contains primarily orientation along the cir-

cumferential or hoop direction and hence will exhibit me-

chanical anisotropy.

To generate a better balance of mechanical properties it

is necessary to create biaxial orientation in the part. Stretch

blow molding is used to accomplish this. In essence the

parison is stretched along the axial direction before being

inflated.Biaxialorientationisspecificallyrequiredinlarge

containers for fluids. For example, bottles for carbonated

beveragesaretypicallyprocessedbymeansofstretchblow

molding.

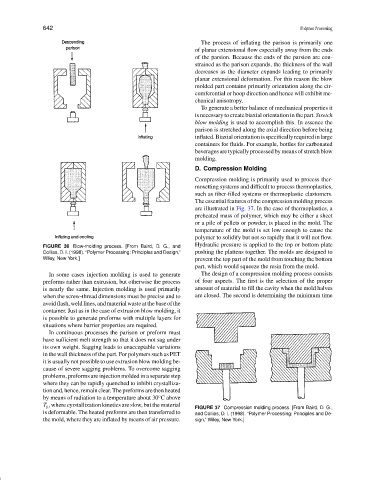

D. Compression Molding

Compression molding is primarily used to process ther-

mosetting systems and difficult to process thermoplastics,

such as fiber-filled systems or thermoplastic elastomers.

The essential features of the compression molding process

are illustrated in Fig. 37. In the case of thermoplastics, a

preheated mass of polymer, which may be either a sheet

or a pile of pellets or powder, is placed in the mold. The

temperature of the mold is set low enough to cause the

polymer to solidify but not so rapidly that it will not flow.

FIGURE 36 Blow-molding process. [From Baird, D. G., and Hydraulic pressure is applied to the top or bottom plate

Collias, D. I. (1998). “Polymer Processing: Principles and Design,” pushing the plattens together. The molds are designed to

Wiley, New York.] prevent the top part of the mold from touching the bottom

part, which would squeeze the resin from the mold.

In some cases injection molding is used to generate The design of a compression molding process consists

preforms rather than extrusion, but otherwise the process of four aspects. The first is the selection of the proper

is nearly the same. Injection molding is used primarily amount of material to fill the cavity when the mold halves

when the screw-thread dimensions must be precise and to are closed. The second is determining the minimum time

avoidflash,weldlines,andmaterialwasteatthebaseofthe

container. Just as in the case of extrusion blow molding, it

is possible to generate preforms with multiple layers for

situations where barrier properties are required.

In continuous processes the parison or preform must

have sufficient melt strength so that it does not sag under

its own weight. Sagging leads to unacceptable variations

in the wall thickness of the part. For polymers such as PET

it is usually not possible to use extrusion blow molding be-

cause of severe sagging problems. To overcome sagging

problems, preforms are injection molded in a separate step

where they can be rapidly quenched to inhibit crystalliza-

tionand,hence,remainclear.Thepreformsarethenheated

by means of radiation to a temperature about 30 C above

◦

T g , where cyrstallization kinetics are slow, but the material

FIGURE 37 Compression molding process. [From Baird, D. G.,

is deformable. The heated preforms are then transferred to and Collias, D. I. (1998). “Polymer Processing: Principles and De-

the mold, where they are inflated by means of air pressure. sign,” Wiley, New York.]