Page 131 - Academic Press Encyclopedia of Physical Science and Technology 3rd Polymer

P. 131

P1: FMX/LSU P2: GPB/GRD P3: GLQ Final pages

Encyclopedia of Physical Science and Technology EN012c-593 July 26, 2001 15:56

Polymer Processing 637

TSP). At intermediate speeds of 750 to 3500 m/min, the C. Film Blowing

filament tension is increased due to inertia and air drag.

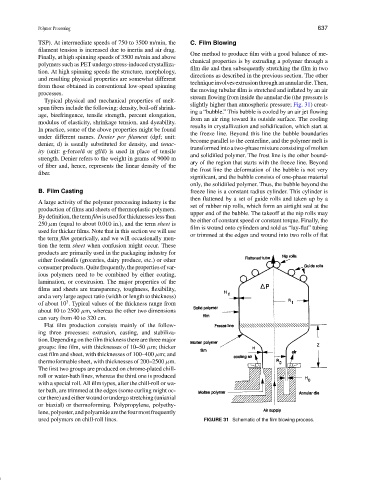

One method to produce film with a good balance of me-

Finally, at high spinning speeds of 3500 m/min and above

chanical properties is by extruding a polymer through a

polymers such as PET undergo stress-induced crystalliza-

film die and then subsequently stretching the film in two

tion. At high spinning speeds the structure, morphology,

directions as described in the previous section. The other

and resulting physical properties are somewhat different

technique involves extrusion through an annular die. Then,

from those obtained in conventional low-speed spinning

the moving tubular film is stretched and inflated by an air

processes.

stream flowing from inside the annular die (the pressure is

Typical physical and mechanical properties of melt-

slightly higher than atmospheric pressure; Fig. 31) creat-

spun fibers include the following: density, boil-off shrink-

ing a “bubble.” This bubble is cooled by an air jet flowing

age, birefringence, tensile strength, percent elongation,

from an air ring toward its outside surface. The cooling

modulus of elasticity, shrinkage tension, and dyeability.

results in crystallization and solidification, which start at

In practice, some of the above properties might be found

the freeze line. Beyond this line the bubble boundaries

under different names. Denier per filament (dpf; unit:

become parallel to the centerline, and the polymer melt is

denier, d) is usually substituted for density, and tenac-

transformed into a two-phase mixture consisting of molten

ity (unit: g-force/d or gf/d) is used in place of tensile

and solidified polymer. The frost line is the other bound-

strength. Denier refers to the weight in grams of 9000 m

ary of the region that starts with the freeze line. Beyond

of fiber and, hence, represents the linear density of the

the frost line the deformation of the bubble is not very

fiber.

significant, and the bubble consists of one-phase material

only, the solidified polymer. Thus, the bubble beyond the

B. Film Casting freeze line is a constant radius cylinder. This cylinder is

then flattened by a set of guide rolls and taken up by a

A large activity of the polymer processing industry is the

set of rubber nip rolls, which form an airtight seal at the

production of films and sheets of thermoplastic polymers.

upper end of the bubble. The takeoff at the nip rolls may

By definition, the term film is used for thicknesses less than

be either of constant speed or constant torque. Finally, the

250 µm (equal to about 0.010 in.), and the term sheet is

film is wound onto cylinders and sold as “lay-flat” tubing

used for thicker films. Note that in this section we will use

or trimmed at the edges and wound into two rolls of flat

the term film generically, and we will occasionally men-

tion the term sheet when confusion might occur. These

products are primarily used in the packaging industry for

either foodstuffs (groceries, dairy produce, etc.) or other

consumer products. Quite frequently, the properties of var-

ious polymers need to be combined by either coating,

lamination, or coextrusion. The major properties of the

films and sheets are transparency, toughness, flexibility,

and a very large aspect ratio (width or length to thickness)

3

of about 10 . Typical values of the thickness range from

about 10 to 2500 µm, whereas the other two dimensions

can vary from 40 to 320 cm.

Flat film production consists mainly of the follow-

ing three processes: extrusion, casting, and stabiliza-

tion. Depending on the film thickness there are three major

groups: fine film, with thicknesses of 10–50 µm; thicker

cast film and sheet, with thicknesses of 100–400 µm; and

thermoformable sheet, with thicknesses of 200–2500 µm.

The first two groups are produced on chrome-plated chill-

roll or water-bath lines, whereas the third one is produced

with a special roll. All film types, after the chill-roll or wa-

ter bath, are trimmed at the edges (some curling might oc-

curthere)andeitherwoundorundergostretching(uniaxial

or biaxial) or thermoforming. Polypropylene, polyethy-

lene,polyester,andpolyamidearethefourmostfrequently

used polymers on chill-roll lines. FIGURE 31 Schematic of the film blowing process.