Page 127 - Academic Press Encyclopedia of Physical Science and Technology 3rd Polymer

P. 127

P1: FMX/LSU P2: GPB/GRD P3: GLQ Final pages

Encyclopedia of Physical Science and Technology EN012c-593 July 26, 2001 15:56

Polymer Processing 633

uniformity in flow rate across the die width, the choker die by means of the mandrel support tip. The melt then

bar can be used to adjust the flow rate locally. The die lips passes over the spider legs which support the mandrel, and

provide the final film thickness and can also be adjusted through a converging annular region, which for pipes is

◦

◦

locally to account for a nonuniform flow rate or nonuni- usually 10 to 15 . The converging region is followed by

form die swell. The manifold design shown in Fig. 25 an annular region with parallel walls which imparts the

is referred to as a coathanger. Other designs include the final dimensions to the pipe. The outer diameter of the

T-die and the fishtail die. pipe can range from a few millimeters to approximately

1.6 m. The ratio of the mandrel radius to outer wall ra-

dius usually falls in the range of 0.8 to 0.925. The spider

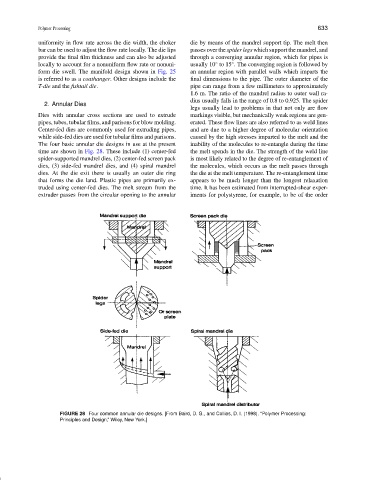

2. Annular Dies

legs usually lead to problems in that not only are flow

Dies with annular cross sections are used to extrude markings visible, but mechanically weak regions are gen-

pipes, tubes, tubular films, and parisons for blow molding. erated. These flow lines are also referred to as weld lines

Center-fed dies are commonly used for extruding pipes, and are due to a higher degree of molecular orientation

while side-fed dies are used for tubular films and parisons. caused by the high stresses imparted to the melt and the

The four basic annular die designs in use at the present inability of the molecules to re-entangle during the time

time are shown in Fig. 28. These include (1) center-fed the melt spends in the die. The strength of the weld line

spider-supported mandrel dies, (2) center-fed screen pack is most likely related to the degree of re-entanglement of

dies, (3) side-fed mandrel dies, and (4) spiral mandrel the molecules, which occurs as the melt passes through

dies. At the die exit there is usually an outer die ring the die at the melt temperature. The re-entanglement time

that forms the die land. Plastic pipes are primarily ex- appears to be much longer than the longest relaxation

truded using center-fed dies. The melt stream from the time. It has been estimated from interrupted-shear exper-

extruder passes from the circular opening to the annular iments for polystyrene, for example, to be of the order

FIGURE 28 Four common annular die designs. [From Baird, D. G., and Collias, D. I. (1998). “Polymer Processing:

Principles and Design,” Wiley, New York.]