Page 123 - Academic Press Encyclopedia of Physical Science and Technology 3rd Polymer

P. 123

P1: FMX/LSU P2: GPB/GRD P3: GLQ Final pages

Encyclopedia of Physical Science and Technology EN012c-593 July 26, 2001 15:56

Polymer Processing 629

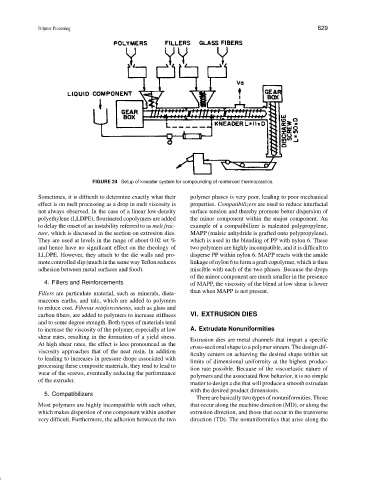

FIGURE 24 Setup of kneader system for compounding of reinforced thermoplastics.

Sometimes, it is difficult to determine exactly what their polymer phases is very poor, leading to poor mechanical

effect is on melt processing as a drop in melt viscosity is properties. Compatibilizers are used to reduce interfacial

not always observed. In the case of a linear low-density surface tension and thereby promote better dispersion of

polyethylene (LLDPE), flourinated copolymers are added the minor component within the major component. An

to delay the onset of an instability referred to as melt frac- example of a compatibilizer is maleated polypropylene,

ture, which is discussed in the section on extrusion dies. MAPP (maleic anhydride is grafted onto polypropylene),

They are used at levels in the range of about 0.02 wt % which is used in the blending of PP with nylon 6. These

and hence have no significant effect on the rheology of two polymers are highly incompatible, and it is difficult to

LLDPE. However, they attach to the die walls and pro- disperse PP within nylon 6. MAPP reacts with the amide

mote controlled slip (much in the same way Teflon reduces linkage of nylon 6 to form a graft copolymer, which is then

adhesion between metal surfaces and food). miscible with each of the two phases. Because the drops

of the minor component are much smaller in the presence

4. Fillers and Reinforcements of MAPP, the viscosity of the blend at low shear is lower

than when MAPP is not present.

Fillers are particulate material, such as minerals, diata-

maceous earths, and talc, which are added to polymers

to reduce cost. Fibrous reinforcements, such as glass and

carbon fibers, are added to polymers to increase stiffness VI. EXTRUSION DIES

and to some degree strength. Both types of materials tend

to increase the viscosity of the polymer, especially at low A. Extrudate Nonuniformities

shear rates, resulting in the formation of a yield stress.

Extrusion dies are metal channels that impart a specific

At high shear rates, the effect is less pronounced as the

cross-sectional shape to a polymer stream. The design dif-

viscosity approaches that of the neat resin. In addition

ficulty centers on achieving the desired shape within set

to leading to increases in pressure drops associated with

limits of dimensional uniformity at the highest produc-

processing these composite materials, they tend to lead to

tion rate possible. Because of the viscoelastic nature of

wear of the screws, eventually reducing the performance

polymers and the associated flow behavior, it is no simple

of the extruder.

matter to design a die that will produce a smooth extrudate

with the desired product dimensions.

5. Compatibilizers

There are basically two types of nonuniformities. Those

Most polymers are highly incompatible with each other, that occur along the machine direction (MD), or along the

which makes dispersion of one component within another extrusion direction, and those that occur in the transverse

very difficult. Furthermore, the adhesion between the two direction (TD). The nonuniformities that arise along the