Page 122 - Academic Press Encyclopedia of Physical Science and Technology 3rd Polymer

P. 122

P1: FMX/LSU P2: GPB/GRD P3: GLQ Final pages

Encyclopedia of Physical Science and Technology EN012c-593 July 26, 2001 15:56

628 Polymer Processing

C. Additives Affecting Polymer Processability

A wide variety of additives are used to enhance the proper-

ties and processing performance of polymers. We empha-

size only those additives which are incorporated for the

purpose of enhancing processibility or are added for some

other reason but lead to significant changes in polymer

processibility.

1. Antioxidants

Antioxidants are compounds that retard oxidation and

hence degradation of the polymer. The susceptibility of

polymers to oxidation starts with the formation of free

radicals on exposure to heat, UV radiation, ozone, metal-

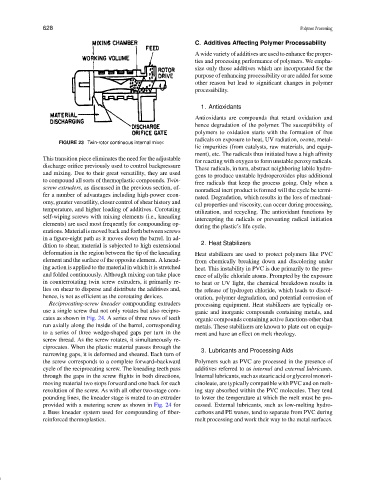

FIGURE 23 Twin-rotor continuous internal mixer.

lic impurities (from catalysts, raw materials, and equip-

ment), etc. The radicals thus initiated have a high affinity

This transition piece eliminates the need for the adjustable

for reacting with oxygen to form unstable peroxy radicals.

discharge orifice previously used to control backpressure

These radicals, in turn, abstract neighboring labile hydro-

and mixing. Due to their great versatility, they are used

gens to produce unstable hydroperoxides plus additional

to compound all sorts of thermoplastic compounds. Twin-

free radicals that keep the process going. Only when a

screw extruders, as discussed in the previous section, of-

nonradical inert product is formed will the cycle be termi-

fer a number of advantages including high-power econ-

nated. Degradation, which results in the loss of mechani-

omy, greater versatility, closer control of shear history and

cal properties and viscosity, can occur during processing,

temperature, and higher loading of additives. Corotating

utilization, and recycling. The antioxidant functions by

self-wiping screws with mixing elements (i.e., kneading

intercepting the radicals or preventing radical initiation

elements) are used most frequently for compounding op-

during the plastic’s life cycle.

erations. Material is moved back and forth between screws

in a figure-eight path as it moves down the barrel. In ad-

2. Heat Stabilizers

dition to shear, material is subjected to high extensional

deformation in the region between the tip of the kneading Heat stabilizers are used to protect polymers like PVC

element and the surface of the opposite element. A knead- from chemically breaking down and discoloring under

ing action is applied to the material in which it is stretched heat. This instability in PVC is due primarily to the pres-

and folded continuously. Although mixing can take place ence of allylic chloride atoms. Prompted by the exposure

in counterrotating twin screw extruders, it primarily re- to heat or UV light, the chemical breakdown results in

lies on shear to disperse and distribute the additives and, the release of hydrogen chloride, which leads to discol-

hence, is not as efficient as the corotating devices. oration, polymer degradation, and potential corrosion of

Reciprocating-screw kneader compounding extruders processing equipment. Heat stabilizers are typically or-

use a single screw that not only rotates but also recipro- ganic and inorganic compounds containing metals, and

cates as shown in Fig. 24. A series of three rows of teeth organic compounds containing active functions other than

run axially along the inside of the barrel, corresponding metals. These stabilizers are known to plate out on equip-

to a series of three wedge-shaped gaps per turn in the ment and have an effect on melt rheology.

screw thread. As the screw rotates, it simultaneously re-

ciprocates. When the plastic material passes through the 3. Lubricants and Processing Aids

narrowing gaps, it is deformed and sheared. Each turn of

the screw corresponds to a complete forward–backward Polymers such as PVC are processed in the presence of

cycle of the reciprocating screw. The kneading teeth pass additives referred to as internal and external lubricants.

through the gaps in the screw flights in both directions, Internal lubricants, such as stearic acid or glycerol monori-

moving material two stops forward and one back for each cinoleate, are typically compatible with PVC and on melt-

revolution of the screw. As with all other two-stage com- ing stay absorbed within the PVC molecules. They tend

pounding lines, the kneader stage is mated to an extruder to lower the temperature at which the melt must be pro-

provided with a metering screw as shown in Fig. 24 for cessed. External lubricants, such as low-melting hydro-

a Buss kneader system used for compounding of fiber- carbons and PE waxes, tend to separate from PVC during

reinforced thermoplastics. melt processing and work their way to the metal surfaces.