Page 117 - Academic Press Encyclopedia of Physical Science and Technology 3rd Polymer

P. 117

P1: FMX/LSU P2: GPB/GRD P3: GLQ Final pages

Encyclopedia of Physical Science and Technology EN012c-593 July 26, 2001 15:56

Polymer Processing 623

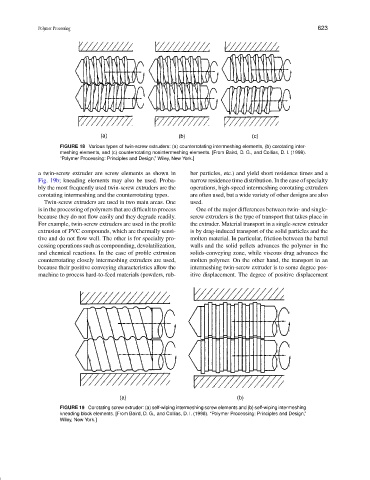

FIGURE 18 Various types of twin-screw extruders: (a) counterrotating intermeshing elements, (b) corotating inter-

meshing elements, and (c) counterrotating nonintermeshing elements. [From Baird, D. G., and Collias, D. I. (1998).

“Polymer Processing: Principles and Design,” Wiley, New York.]

a twin-screw extruder are screw elements as shown in ber particles, etc.) and yield short residence times and a

Fig. 19b; kneading elements may also be used. Proba- narrow residence time distribution. In the case of specialty

bly the most frequently used twin-screw extruders are the operations, high-speed intermeshing corotating extruders

corotating intermeshing and the counterrotating types. are often used, but a wide variety of other designs are also

Twin-screw extruders are used in two main areas. One used.

is in the processing of polymers that are difficult to process One of the major differences between twin- and single-

because they do not flow easily and they degrade readily. screw extruders is the type of transport that takes place in

For example, twin-screw extruders are used in the profile the extruder. Material transport in a single-screw extruder

extrusion of PVC compounds, which are thermally sensi- is by drag-induced transport of the solid particles and the

tive and do not flow well. The other is for specialty pro- molten material. In particular, friction between the barrel

cessing operations such as compounding, devolatilization, walls and the solid pellets advances the polymer in the

and chemical reactions. In the case of profile extrusion solids-conveying zone, while viscous drag advances the

counterrotating closely intermeshing extruders are used, molten polymer. On the other hand, the transport in an

because their positive conveying characteristics allow the intermeshing twin-screw extruder is to some degree pos-

machine to process hard-to-feed materials (powders, rub- itive displacement. The degree of positive displacement

FIGURE 19 Corotating screw extruder: (a) self-wiping intermeshing screw elements and (b) self-wiping intermeshing

kneading block elements. [From Baird, D. G., and Collias, D. I. (1998). “Polymer Processing: Principles and Design,”

Wiley, New York.]