Page 113 - Academic Press Encyclopedia of Physical Science and Technology 3rd Polymer

P. 113

P1: FMX/LSU P2: GPB/GRD P3: GLQ Final pages

Encyclopedia of Physical Science and Technology EN012c-593 July 26, 2001 15:56

Polymer Processing 619

flow is generated. The device can be operated by either

applying a constant squeeze rate or a constant force. The

device is very useful for making viscosity measurements

5

on fluids with high viscosity (e.g., η> 10 Pa sec) such as

composite materials containing long-fiber reinforcement

or propellants.

F. Effect of Molar Mass on Viscosity

Molar mass (M) has a significant effect on the rheological

properties of polymer melts and hence on their processing

performance. At low molar mass, i.e., below some critical

molar mass (M c ), for flexible chain polymers η 0 depends

on M w , while above M c , η 0 depends on M w to the 3.4 to

3.6 power for most flexible linear polymer chains:

M w for M w < M c

η 0 ∝ 3.4 . (21)

M

w for M w > M c

The 3.4 power dependence has been observed experimen-

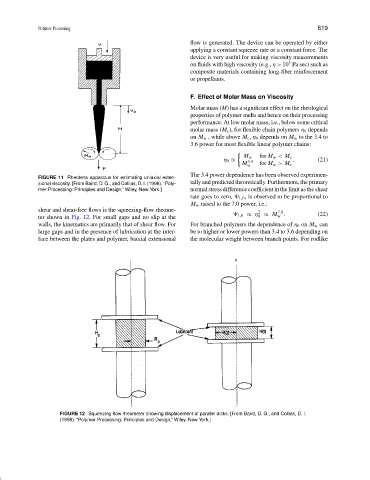

FIGURE 11 Rheotens apparatus for estimating uniaxial exten-

tally and predicted theoretically. Furthermore, the primary

sional viscosity. [From Baird, D. G., and Collias, D. I. (1998). “Poly-

mer Processing: Principles and Design,” Wiley, New York.] normal stress difference coefficient in the limit as the shear

rate goes to zero, 1,0 , is observed to be proportional to

M w raised to the 7.0 power, i.e.:

shear and shear-free flows is the squeezing-flow rheome- 2 7.0

1,0 ∝ η ∝ M . (22)

ter shown in Fig. 12. For small gaps and no slip at the 0 w

walls, the kinematics are primarily that of shear flow. For For branched polymers the dependence of η 0 on M w can

large gaps and in the presence of lubrication at the inter- be to higher or lower powers than 3.4 to 3.6 depending on

face between the plates and polymer, biaxial extensional the molecular weight between branch points. For rodlike

FIGURE 12 Squeezing-flow rheometer showing displacement of parallel disks. [From Baird, D. G., and Collias, D. I.

(1998). “Polymer Processing: Principles and Design,” Wiley, New York.]