Page 109 - Academic Press Encyclopedia of Physical Science and Technology 3rd Polymer

P. 109

P1: FMX/LSU P2: GPB/GRD P3: GLQ Final pages

Encyclopedia of Physical Science and Technology EN012c-593 July 26, 2001 15:56

Polymer Processing 615

where ˙ε is the extension rate and b is a constant that is does not lead to a strong degree of molecular orientation.

either 0 or 1. When b = 0 and ˙ε > 0, the flow is uniaxial Furthermore, the rheological response can be significantly

extensional flow. When b = 0, but ˙ε < 0, the flow is equib- different for a polymer in extensional flow versus shear

iaxial extensional flow. When b = 1 and ˙ε > 0, the flow is flow.

called planar extensional flow. Various types of shear flow experiments are used in

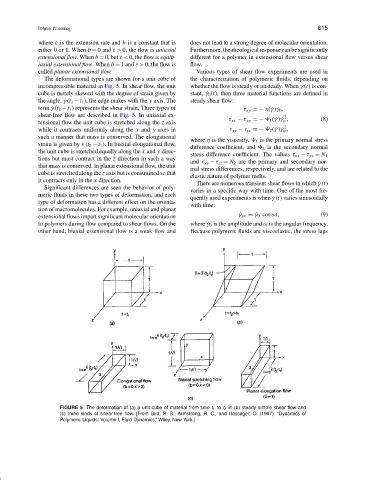

The deformational types are shown for a unit cube of the characterization of polymeric fluids, depending on

incompressible material in Fig. 5. In shear flow, the unit whether the flow is steady or unsteady. When ˙γ (t) is con-

cube is merely skewed with the degree of strain given by stant, ˙γ 0 (t), then three material functions are defined in

the angle, ˙γ (t 2 − t 1 ), the edge makes with the y axis. The steady shear flow:

term ˙γ (t 2 − t 1 ) represents the shear strain. Three types of τ xy =− η( ˙γ ) ˙γ 0 ,

shear-free flow are described in Fig. 5. In uniaxial ex- 2

τ xx − τ yy =− 1 ( ˙γ ) ˙γ , (8)

tensional flow the unit cube is stretched along the z axis 0

2

while it contracts uniformly along the x and y axes in τ yy − τ zz =− 2 ( ˙γ ) ˙γ ,

0

such a manner that mass is conserved. The elongational

where η is the viscosity, 1 is the primary normal stress

strain is given by ˙ε (t 2 − t 1 ). In biaxial elongational flow,

difference coefficient, and 2 is the secondary normal

the unit cube is stretched equally along the x and y direc-

stress difference coefficient. The values τ xx − τ yy = N 1

tions but must contract in the z direction in such a way

and τ yy − τ zz = N 2 are the primary and secondary nor-

that mass is conserved. In planar extensional flow, the unit

mal stress differences, respectively, and are related to the

cube is stretched along the z axis but is constrained so that

elastic nature of polymer melts.

it contracts only in the x direction.

There are numerous transient shear flows in which ˙γ (t)

Significant differences are seen the behavior of poly-

varies in a specific way with time. One of the most fre-

meric fluids in these two types of deformation, and each

quently used experiments is when ˙γ (t) varies sinusoidally

type of deformation has a different effect on the orienta-

with time:

tion of macromolecules. For example, uniaxial and planar

extensional flows impart significant molecular orientation ˙ γ yx = ˙γ 0 cos ωt, (9)

to polymers during flow compared to shear flows. On the where ˙γ 0 is the amplitude and ω is the angular frequency.

other hand, biaxial extensional flow is a weak flow and Because polymeric fluids are viscoelastic, the stress lags

FIGURE 5 The deformation of (a) a unit cube of material from time t 1 to t 2 in (b) steady simple shear flow and

(c) three kinds of shear-free flow. [From Bird, R. B., Armstrong, R. C., and Hassager, O. (1987). “Dynamics of

Polymeric Liquids: Volume I, Fluid Dynamics,” Wiley, New York.]