Page 121 - Academic Press Encyclopedia of Physical Science and Technology 3rd Polymer

P. 121

P1: FMX/LSU P2: GPB/GRD P3: GLQ Final pages

Encyclopedia of Physical Science and Technology EN012c-593 July 26, 2001 15:56

Polymer Processing 627

ratio for the two modes of bursting, i.e., tip streaming Continuous compounders are for the most part designed

(for p < 0.1) and regular bursting. Tip streaming refers to around one or more extruders, either of the single- or twin-

the situation where droplets assume a sigmoidal shape screw type. The most versatile screw-extruder compound-

with tiny droplets shedding off the tops. The important ing lines are the so-called two-stage compounding lines,

feature shown in Fig. 20 is the inability of shear flows to which combine high-performance continuous melt mix-

cause droplet breakup at viscosity ratios exceeding 3.5, ers, such as planetary gear extruders, twin-screw extrud-

while for shear-free flows (i.e., extensional flow) breakup ers, twin-rotor continuous mixers, and reciprocating screw

occurs over a wide range of viscosity ratios. kneaders, with a single-screw extruder. These melt mixers

provide excellent control over shear, stock temperature,

dwell time, and homogeneity. The second stage, usually a

B. Commercial Compounding Lines short single-screw extruder, receives the melt and meters

it to a strand die. Vacuum venting is normally available in

Compounding lines fall into two broad categories: batch

the transition area between the extruders, which ensures

and continuous systems. A commonly used batch mixer

that any volatile matter is extracted from the plastics. Nor-

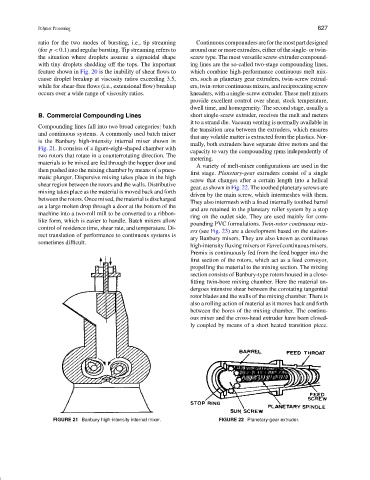

is the Banbury high-intensity internal mixer shown in

mally, both extruders have separate drive motors and the

Fig. 21. It consists of a figure-eight-shaped chamber with

capacity to vary the compounding rpms independently of

two rotors that rotate in a counterrotating direction. The

metering.

materials to be mixed are fed through the hopper door and

A variety of melt-mixer configurations are used in the

then pushed into the mixing chamber by means of a pneu-

first stage. Planetary-gear extruders consist of a single

matic plunger. Dispersive mixing takes place in the high

screw that changes after a certain length into a helical

shear region between the rotors and the walls. Distributive

gear, as shown in Fig. 22. The toothed planetary screws are

mixing takes place as the material is moved back and forth

driven by the main screw, which intermeshes with them.

between the rotors. Once mixed, the material is discharged

They also intermesh with a fixed internally toothed barrel

as a large molten drop through a door at the bottom of the

and are retained in the planetary roller system by a stop

machine into a two-roll mill to be converted to a ribbon-

ring on the outlet side. They are used mainly for com-

like form, which is easier to handle. Batch mixers allow

pounding PVC formulations. Twin-rotor continuous mix-

control of residence time, shear rate, and temperature. Di-

ers (see Fig. 23) are a development based on the station-

rect translation of performance to continuous systems is

ary Banbury mixers. They are also known as continuous

sometimes difficult.

high-intensity fluxing mixers or Farrel continuous mixers.

Premix is continuously fed from the feed hopper into the

first section of the rotors, which act as a feed conveyor,

propelling the material to the mixing section. The mixing

section consists of Banbury-type rotors housed in a close-

fitting twin-bore mixing chamber. Here the material un-

dergoes intensive shear between the corotating tangential

rotor blades and the walls of the mixing chamber. There is

also a rolling action of material as it moves back and forth

between the bores of the mixing chamber. The continu-

ous mixer and the cross-head extruder have been closed-

ly coupled by means of a short heated transition piece.

FIGURE 21 Banbury high-intensity internal mixer. FIGURE 22 Planetary-gear extruder.