Page 124 - Academic Press Encyclopedia of Physical Science and Technology 3rd Polymer

P. 124

P1: FMX/LSU P2: GPB/GRD P3: GLQ Final pages

Encyclopedia of Physical Science and Technology EN012c-593 July 26, 2001 15:56

630 Polymer Processing

MD are usually due to pressure and temperature variations direct relation to extrudate uniformity, while the flow be-

that affect the flow rate, the rheological properties of the havior in contractions may only be indirectly related to

melt, and to some degree the die design. The irregulari- extrudate uniformity. In this section, for illustrative pur-

ties that occur in the TD are due nearly totally to the die poses, we present results based primarily on studies in the

design, but in some cases the rheological properties are capillary geometry. One must recognize that the exten-

responsible for irregularities. sion of results from a capillary to other geometries may

In the case of the MD, variations in the flow rate due be difficult to make quantitatively.

to pressure or temperature variations in the pumping de-

vice are the main cause of the irregularities. However,

B. Extrusion Instabilities

flow instabilities associated with the phenomena of melt

fracture (discussed later in this section) and draw reso- The limiting factor in the extrusion rate of polymeric fluids

nance (discussed in Section VII) can lead to variations is the onset of a low Reynolds number instability called

in the dimensions of the extrudate. These variations are melt fracture. The onset of melt fracture leads to varying

closely connected to the rheological properties of the melt, degrees of imperfections that may affect only the clarity

but die design can at least alleviate the severity of the of a material on one hand, or on the other, may be so

irregularities. severe as to significantly reduce the physical properties.

The TD variations are nearly totally due to die de- There are basically five types of melt fracture: sharkskin,

sign. The major problem is to design a feed system (i.e., ripple, bamboo, wavy, and severe. These types of melt

manifold) that will distribute the melt uniformly to the fracture are shown in Figs. 26 and 27. Sharkskin is shown

shaping portion of the die (see Fig. 25 for definition of in Fig. 26 for a LLDPE. At the lowest apparent shear rate

parts of a die). In the event this is not possible, then it the extrudate is smooth but at an apparent shear rate of

−1

must be possible to adjust the die lips in such a way that ˙ γ a = 112 sec , the extrudate exhibits a mild roughness,

the fluid will leave the die with a uniform thickness. Even called sharkskin, which affects the appearance of the sur-

when the manifold is designed to feed the die uniformly, face. This type of fracture is extremely detrimental to the

the phenomenon of die swell can affect the degree of uni- manufacture of packaging films, which must meet certain

formity across the die. Because the degree of swell may requirements for clarity. As ˙γ a is increased, another form

−1

vary nonuniformly over the cross section due to variations of fracture arises. At ˙γ a = 750 sec , the fracture present

in the deformation history, then the die lips (main shaping is called bamboo. Finally, at ˙γ a of 2250 sec −1 the fracture

section) may have to be designed to compensate for this. is severe. LLDPE does not seem to exhibit wavy fracture.

Three phenomena are associated with the flow behavior HDPE does not seem to exhibit sharkskin, but does seem

of polymeric fluids that must be considered in the design to exhibit bamboo (sometimes referred to as spurt or slip-

of extrusion dies: pressure drops in contractions (or expan- stick) fracture at lower shear rates as shown in Fig. 27. As

sions), die swell, and melt fracture. The latter two bear a ˙ γ a is increased, HDPE is observed to exhibit the wavy form

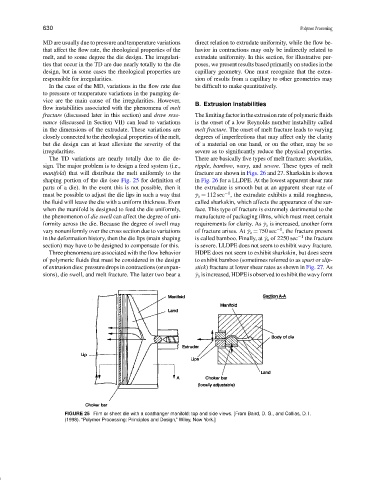

FIGURE 25 Film or sheet die with a coathanger manifold: top and side views. [From Baird, D. G., and Collias, D. I.

(1998). “Polymer Processing: Principles and Design,” Wiley, New York.]