Page 201 - Energy from Toxic Organic Waste for Heat and Power Generation

P. 201

Power Generation From Renewable Energy Sources 179

80

70

60

Conversion (%) 40

50

30

20

10

0

0 40 80 120 160

Time (s)

Fig. 11.19 Time optimization catalytic degradation.

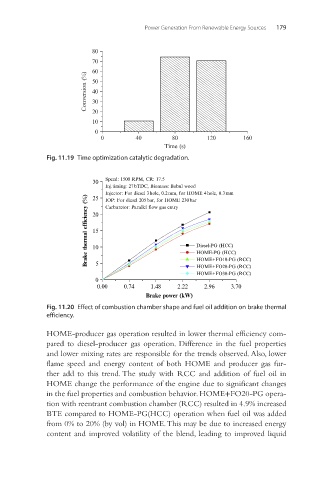

30 Speed: 1500 RPM, CR: 17.5

Inj.timing: 27 bTDC, Biomass: Babul wood

Injector: For diesel 3hole, 0.2mm, for HOME 4hole, 0.3mm

25

Brake thermal efficiency (%) 20 Diesel-PG (HCC)

IOP: For diesel 205bar, for HOME 230bar

Carburetor: Parallel flow gas entry

15

10

HOME-PG (HCC)

HOME+FO10-PG (RCC)

5

HOME+FO20-PG (RCC)

HOME+FO30-PG (RCC)

0

0.00 0.74 1.48 2.22 2.96 3.70

Brake power (kW)

Fig. 11.20 Effect of combustion chamber shape and fuel oil addition on brake thermal

efficiency.

HOME-producer gas operation resulted in lower thermal efficiency com-

pared to diesel-producer gas operation. Difference in the fuel properties

and lower mixing rates are responsible for the trends observed. Also, lower

flame speed and energy content of both HOME and producer gas fur-

ther add to this trend. The study with RCC and addition of fuel oil in

HOME change the performance of the engine due to significant changes

in the fuel properties and combustion behavior. HOME+FO20-PG opera-

tion with reentrant combustion chamber (RCC) resulted in 4.9% increased

BTE compared to HOME-PG(HCC) operation when fuel oil was added

from 0% to 20% (by vol) in HOME. This may be due to increased energy

content and improved volatility of the blend, leading to improved liquid