Page 227 - Engineered Interfaces in Fiber Reinforced Composites

P. 227

Chapter 5. Surface treutments of fibers and eflects on composite properties 209

However, there are several common requirements that a coating technique should

satisfy. They are:

(1) the coating should not impair the properties of the substrate fiber,

(2) the deposition process must be compatible with the fiber,

(3) the coating deposition should be a continuous process, and

(4) the coating technique must be capable of coating the fiber with a uniform

thickness.

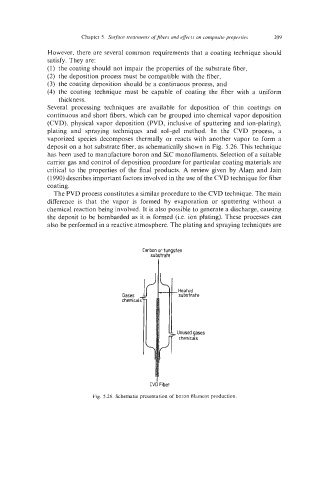

Several processing techniques are available for deposition of thin coatings on

continuous and short fibers, which can be grouped into chemical vapor deposition

(CVD), physical vapor deposition (PVD, inclusive of sputtering and ion-plating),

plating and spraying techniques and sol-gel method. In the CVD process, a

vaporized species decomposes thermally or reacts with another vapor to form a

deposit on a hot substrate fiber, as schematically shown in Fig. 5.26. This technique

has been used to manufacture boron and Sic monofilaments. Selection of a suitable

carrier gas and control of deposition procedure for particular coating materials are

critical to the properties of the final products. A review given by Alam and Jain

(1990) describes important factors involved in the use of the CVD technique for fiber

coating.

The PVD process constitutes a similar procedure to the CVD technique. The main

difference is that the vapor is formed by evaporation or sputtering without a

chemical reaction being involved. It is also possible to generate a discharge, causing

the deposit to be bombarded as it is formed (Le. ion plating). These processes can

also be performed in a reactive atmosphere. The plating and spraying techniques are

Carbon or tungsten

substrate

Heated

substrate

-Unused

t chemicals gases

CVd Fiber

Fig. 5.26. Schematic presentation of boron filament production.