Page 235 - Engineered Interfaces in Fiber Reinforced Composites

P. 235

Chapter 5. Surface treutments of jibers and effects on composite properties 217

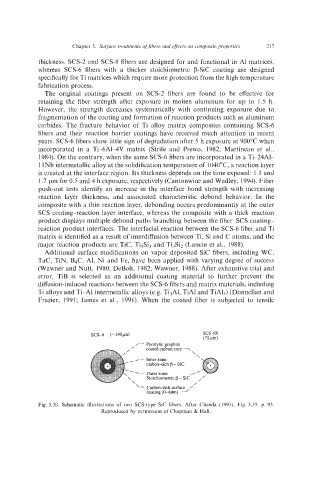

thickness. SCS-2 and SCS-8 fibers are designed for and functional in A1 matrices,

whereas SCS-6 fibers with a thicker stoichiometric p-Sic coating are designed

specifically for Ti matrices which require more protection from the high temperature

fabrication process.

The original coatings present on SCS-2 fibers are found to be effective for

retaining the fiber strength after exposure in molten aluminum for up to 1.5 h.

However, the strength decreases systematically with continuing exposure due to

fragmentation of the coating and formation of reaction products such as aluminum

carbides. The fracture behavior of Ti alloy matrix composites containing SCS-6

fibers and their reaction barrier coatings have received much attention in recent

years. SCS-6 fibers show little sign of degradation after 5 h exposure at 900°C when

incorporated in a Ti-6A1-4V matrix (Strife and Prewo, 1982; Martineau et al.,

1984). On the contrary, when the same SCS-6 fibers are incorporated in a Ti-24A1-

11Nb intermetallic alloy at the solidification temperature of 1O4O0C, a reaction layer

is created at the interface region. Its thickness depends on the time exposed: 1.1 and

1.7 pm for 0.5 and 4 h exposure, respectively (Cantonwine and Wadley, 1994). Fiber

push-out tests identify an increase in the interface bond strength with increasing

reaction layer thickness, and associated characteristic debond behavior. In the

composite with a thin reaction layer, debonding occurs predominantly at the outer

SCS coating-reaction layer interface, whereas the composite with a thick reaction

product displays multiple debond paths branching between the fiber-SCS coating-

reaction product interfaces. The interfacial reaction between the SCS-6 fiber and Ti

matrix is identified as a result of interdiffusion between Ti, Si and C atoms, and the

major reaction products are TIC, Ti5Si3 and Ti3Si2 (Lancin et al., 1988).

Additional surface modifications on vapor deposited Sic fibers, including WC,

TaC, TIN, B4C, Al, Ni and Fe, have been applied with varying degree of success

(Wawner and Nutt, 1980; DeBolt, 1982; Wawner, 1988). After exhaustive trial and

error, TiB is selected as an additional coating material to further prevent the

diffusion-induced reactions between the SCS-6 fibers and matrix materials, including

Ti alloys and Ti-A1 intermetallic alloys (e.g. Ti3A1, TiAl and TiA13) (Donnellan and

Frazier, 1991; James et al., 1991). When the coated fiber is subjected to tensile

carbon-nch 6 - Sic

\- Carbon-rich surface. / '

coating(O-4ym) 1

Fig. 5.30. Schematic illustrations of two SCS-type SIC fibers. After Chawla (1993), Fig. 3.35, p. 95.

Reproduced by permission of Chapman & Hall.