Page 233 - Engineered Interfaces in Fiber Reinforced Composites

P. 233

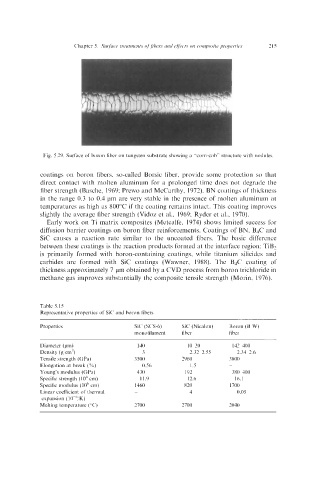

Fig. 5.29. Surface of boron fiber on tungsten substrate showing a "corn-cob" structure with nodules.

coatings on boron fibers, so-called Borsic fiber, provide some protection so that

direct contact with molten aluminum for a prolonged time does not degrade the

fiber strength (Basche, 1969; Prewo and McCarthy, 1972). BN coatings of thickness

in the range 0.3 to 0.4 pm are very stable in the presence of molten aluminum at

temperatures as high as 800°C if the coating remains intact. This coating improves

slightly the average fiber strength (Vidoz et al., 1969; Ryder et al., 1970).

Early work on Ti matrix composites (Metcalfe, 1974) shows limited success for

diffusion barrier coatings on boron fiber reinforcements. Coatings of BN, B4C and

Sic causes a reaction rate similar to the uncoated fibers. The basic difference

between these coatings is the reaction products formed at the interface region: TiB?

is primarily formed with boron-containing coatings, while titanium silicides and

carbides are formed with Sic coatings (Wawner, 1988). The B4C coating of

thickness approximately 7 pm obtained by a CVD process from boron trichloride in

methane gas improves substantially the composite tensile strength (Morin, 1976).

Table 5.15

Representative properties of SIC and boron fibers

Properties Sic (SCS-6) Sic (Nicalon) Boron (BjW)

monofilament fiber fiber

Diameter (pm) 140 10 20 142400

Density (gicm') 3 2.32 2.55 2.34-2.6

Tensile strength (GPd) 3500 2960 3800

Elongation at break (%) 0.56 1.5 -

Young's modulus (GPa) 430 192 380-400

Specific strength (IO6 cm) 11.9 12.6 16.1

Specific modulus (10' cm) 1460 820 I700

Linear coefficient of thermal - 4 0.05

expansion (lO-'/K)

Melting temperature ("C) 2700 2700 2040