Page 302 - Engineered Interfaces in Fiber Reinforced Composites

P. 302

Chapter 7. Improvement of transverse fracture toughness with interface control 283

5.29) allows non-uniform application of coatings on the fiber with a resulting

pattern of intermittently coated and uncoated regions. This condition provides good

bonding in the low spots, while high points are shielded from the matrix by the

coating, allowing extensive interface crack propagation. Graphite and polytetra-

fluoroethylene (PTFE) coatings on boron fibers and a viscous polyurethane coating

on carbon fibers were shown to be effective in avoiding fiber-initiated catastrophic

failure of the composites.

The intermittent bonding concept was further developed by Marston et al. (1974)

and Atkins (1 975). The argument is that as far as there are enough regions of strong

interface, ensuring that the rule of mixtures (RoM) composite strength is retained,

the rest of the composite could have quite a weak interface which may serve to blunt

the running crack by the tensile debonding mechanism (Cook and Gordon, 1964). It

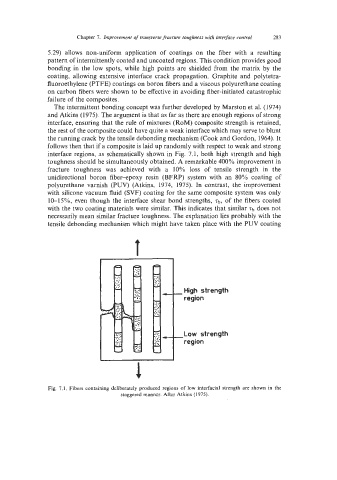

follows then that if a composite is laid up randomly with respect to weak and strong

interface regions, as schematically shown in Fig. 7.1, both high strength and high

toughness should be simultaneously obtained. A remarkable 400% improvement in

fracture toughness was achieved with a 10% loss of tensile strength in the

unidirectional boron fiber-epoxy resin (BFRP) system with an 80% coating of

polyurethane varnish (PUV) (Atkins, 1974, 1975). In contrast, the improvement

with silicone vacuum ffuid (SVF) coating for the same composite system was only

10-15%, even though the interface shear bond strengths, Zb, of the fibers coated

with the two coating materials were similar. This indicates that similar Tb does not

necessarily mean similar fracture toughness. The explanation lies probably with the

tensile debonding mechanism which might have taken place with the PUV coating

T

- High strength

region

- Low strength

region

1

Fig. 7.1. Fibers containing deliberately produced regions of low interfacial strength are shown in the

staggered manner. Aftcr Atkins (1975).