Page 33 - Engineered Interfaces in Fiber Reinforced Composites

P. 33

16 Engineered interfaces in jiber reinforced composites

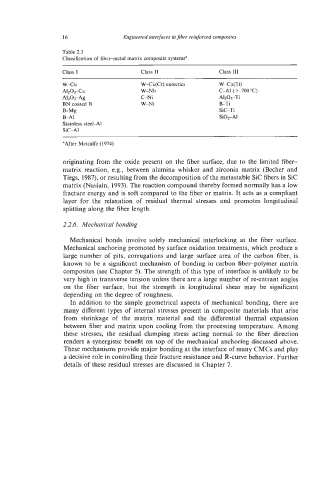

Table 2.3

Classification of fiber-metal matrix composite systemsa

Class I Class I1 Class I11

w-cu W-Cu(Cr) eutectics W-Cu(Ti)

A1203-CU W-Nb C-AI ( > 700 "C)

A1203-Ag C-Ni AI2Q3-Ti

BN coated B W-Ni &Ti

B-Mg Sic-Ti

B-AI Si02-AI

Stainless steel-A1

Sic-AI

aAfter Metcalfe (1974)

originating from the oxide present on the fiber surface, due to the limited fiber-

matrix reaction, e.g., between alumina whisker and zirconia matrix (Becher and

Tiegs, 1987), or resulting from the decomposition of the metastable Sic fibers in Sic

matrix (Naslain, 1993). The reaction compound thereby formed normally has a low

fracture energy and is soft compared to the fiber or matrix. It acts as a compliant

layer for the relaxation of residual thermal stresses and promotes longitudinal

splitting along the fiber length.

2.2.6. Mechanical bonding

Mechanical bonds involve solely mechanical interlocking at the fiber surface.

Mechanical anchoring promoted by surface oxidation treatments, which produce a

large number of pits, corrugations and large surface area of the carbon fiber, is

known to be a significant mechanism of bonding in carbon fiber-polymer matrix

composites (see Chapter 5). The strength of this type of interface is unlikely to be

very high in transverse tension unless there are a large number of re-entrant angles

on the fiber surface, but the strength in longitudinal shear may be significant

depending on the degree of roughness.

In addition to the simple geometrical aspects of mechanical bonding, there are

many different types of internal stresses present in composite materials that arise

from shrinkage of the matrix material and the differential thermal expansion

between fiber and matrix upon cooling from the processing temperature. Among

these stresses, the residual clamping stress acting normal to the fiber direction

renders a synergistic benefit on top of the mechanical anchoring discussed above.

These mechanisms provide major bonding at the interface of many CMCs and play

a decisive role in controlling their fracture resistance and R-curve behavior. Further

details of these residual stresses are discussed in Chapter 7.