Page 365 - Engineered Interfaces in Fiber Reinforced Composites

P. 365

346 Engineered interfaces in jiber reinforced composites

18 1

~16-

n

!2- - without interleaves

g14 - --- with inter leaves

d-

-

2 12

4- L

v)

d

2 10-

L

0

z -

8-

-

(b) Distance from free edge

- 6

20 16 12 8 4 0

(a) Distance from free edge

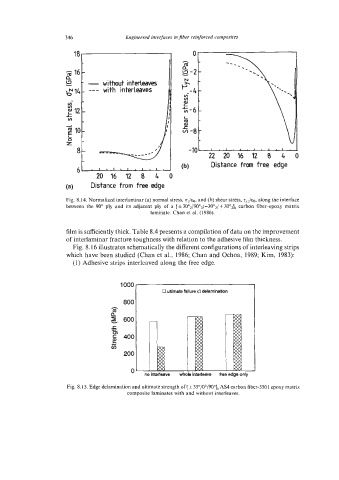

Fig. 8.14. Normalized interlaminar (a) normal stress, uJ~, and (b) shear stress, T,.=/cc,, along the interface

between the 90" ply and its adjacent ply of a [ f 30"2/90"~/-30"2/ + 30°& carbon fiber-epoxy matrix

laminate. Chan et al. (1986).

film is sufficiently thick. Table 8.4 presents a compilation of data on the improvement

of interlaminar fracture toughness with relation to the adhesive film thickness.

Fig. 8.16 illustrates schematically the different configurations of interleaving strips

which have been studied (Chan et al., 1986; Chan and Ochoa, 1989; Kim, 1983):

(1) Adhesive strips interleaved along the free edge.

1000,

0 ultimate failure ICJ delamination

800

3

$. 600

6

m

C 400

Q)

L

tj

200

Fig. 8.1 5. Edge delamination and ultimate strength of [ i 35"/Oo/9O0], AS4 carbon fiber-3501 epoxy matrix

composite laminates with and without interleaves.