Page 62 - Engineered Interfaces in Fiber Reinforced Composites

P. 62

Chapter 3. Measurements of interface/interlaminar properties 45

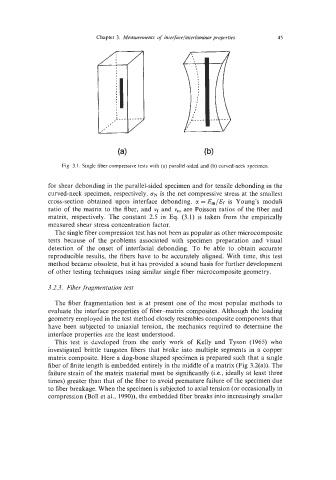

Fig. 3. I. Single fiber compressive tests with (a) parallel-sided and (b) curved-neck specimen

for shear debonding in the parallel-sided specimen and for tensile debonding in the

curved-neck specimen, respectively. CTN is the net compressive stress at the smallest

cross-section obtained upon interface debonding. a = Ern/& is Young’s moduli

ratio of the matrix to the fiber, and vf and v, are Poisson ratios of the fiber and

matrix, respectively. The constant 2.5 in Eq. (3.1) is taken from the empirically

measured shear stress concentration factor.

The single fiber compression test has not been as popular as other microcomposite

tests because of the problems associated with specimen preparation and visual

detection of the onset of interfacial debonding. To be able to obtain accurate

reproducible results, the fibers have to be accurately aligned. With time, this test

method became obsolete, but it has provided a sound basis for further development

of other testing techniques using similar single fiber microcomposite geometry.

3.2.3. Fiber fragmentation test

The fiber fragmentation test is at present one of the most popular methods to

evaluate the interface properties of fiber-matrix composites. Although the loading

geometry employed in the test method closely resembles composite components that

have been subjected to uniaxial tension, the mechanics required to determine the

interface properties are the least understood.

This test is developed from the early work of Kelly and Tyson (1965) who

investigated brittle tungsten fibers that broke into multiple segments in a copper

matrix composite. Here a dog-bone shaped specimen is prepared such that a single

fiber of finite length is embedded entirely in the middle of a matrix (Fig 3.2(a)). The

failure strain of the matrix material must be significantly (Le., ideally at least three

times) greater than that of the fiber to avoid premature failure of the specimen due

to fiber breakage. When the specimen is snbjected to axial tension (or occasionally in

compression (Boll et al., 1990)), the embedded fiber breaks into increasingly smaller