Page 64 - Engineered Interfaces in Fiber Reinforced Composites

P. 64

Chapter 3. Measurements of interfacelinterlaminar properties 47

HI‘/ by = 92.6MPa

End of fragmentation

Acoustic

emission events

I 1 , I

(b) 75 fiber ruptures

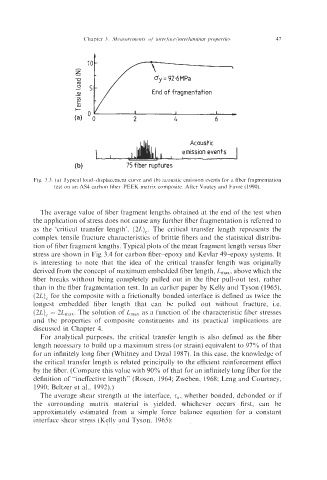

Fig. 3.3. (a) Typical load4isplacement curve and (b) acoustic emission events for a fiber fragmentation

test on an AS4 carbon fiber-PEEK matrix composite. After Vautey and Favre (1990).

The average value of fiber fragment lengths obtained at the end of the test when

the application of stress does not cause any further fiber fragmentation is referred to

as the ‘critical transfer length’, (2L),. The critical transfer length represents the

complex tensile fracture characteristics of brittle fibers and the statistical distribu-

tion of fiber fragment lengths. Typical plots of the mean fragment length versus fiber

stress are shown in Fig 3.4 for carbon fiber-epoxy and Kevlar 49-epoxy systems. It

is interesting to note that the idea of the critical transfer length was originally

derived from the concept of maximum embedded fiber length, Lmax, above which the

fiber breaks without being completely pulled out in the fiber pull-out test, rather

than in the fiber fragmentation test. In an earlier paper by Kelly and Tyson (1965),

(2L), for the composite with a frictionally bonded interface is defined as twice the

longest embedded fiber length that can be pulled out without fracture, i.e.

(2L), = 2Lm,,. The solution of L,,, as a function of the characteristic fiber stresses

and the properties of composite constituents and its practical implications are

discussed in Chapter 4.

For analytical purposes, the critical transfer length is also defined as the fiber

length necessary to build up a maximum stress (or strain) equivalent to 97% of that

for an infinitely long fiber (Whitney and Drzal 1987). In this case, the knowledge of

the critical transfer length is related principally to the efficient reinforcement effect

by the fiber. (Compare this value with 90% of that for an infinitely long fiber for the

definition of “ineffective length” (Rosen, 1964; Zweben, 1968; Leng and Courtney,

1990; Beltzer et al., 1992).)

The average shear strength at the interface, z,, whether bonded, debonded or if

the surrounding matrix material is yielded, whichever occurs first, can be

approximately estimated from a simple force balance equation for a constant

interface shear stress (Kelly and Tyson, 1965):