Page 72 - Engineered Interfaces in Fiber Reinforced Composites

P. 72

Chapter 3. Measurements of interfacelinterlaminar properties 55

0.05-01

mm

Fiber

\

. . . .;. :_.

:. :;. ..A,, J.

MicrodropCt

Thin strip of polymer film Polymer A

(a) film

1 Microvice

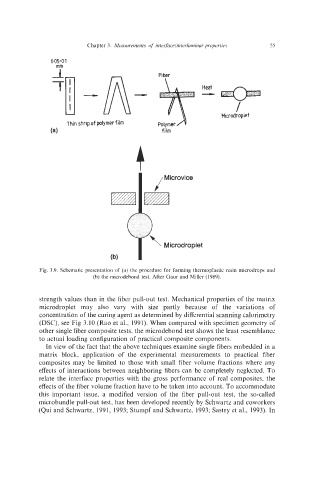

Fig. 3.9. Schematic presentation of (a) the procedure for forming thermoplastic resin microdrops and

(b) the microdebond test. After Gaur and Miller (1989).

strength values than in the fiber pull-out test. Mechanical properties of the matrix

microdroplet may also vary with size partly because of the variations of

concentration of the curing agent as determined by differential scanning calorimetry

(DSC), see Fig 3.10 (Rao et al., 1991). When compared with specimen geometry of

other single fiber composite tests, the microdebond test shows the least resemblance

to actual loading configuration of practical composite components.

In view of the fact that the above techniques examine single fibers embedded in a

matrix block, application of the experimental measurements to practical fiber

composites may be limited to those with small fiber volume fractions where any

effects of interactions between neighboring fibers can be completely neglected. To

relate the interface properties with the gross performance of real composites, the

effects of the fiber volume fraction have to be taken into account. To accommodate

this important issue, a modified version of the fiber pull-out test, the so-called

microbundle pull-out test, has been developed recently by Schwartz and coworkers

(Qui and Schwartz, 1991, 1993; Stumpf and Schwartz, 1993; Sastry et al., 1993). In