Page 76 - Engineered Interfaces in Fiber Reinforced Composites

P. 76

Chapter 3. Measurements of interfacelinterlaminar properties 59

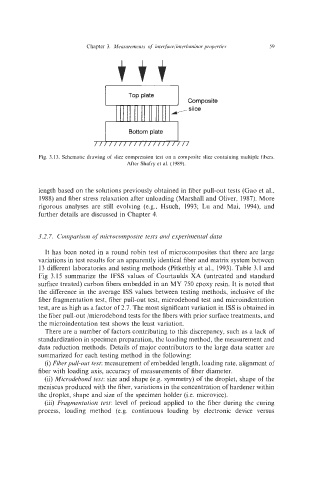

Fig. 3.13. Schematic drawing of slice compression test on a composite slice containing multiple fibers.

After Shafry et al. (1989).

length based on the solutions previously obtained in fiber pull-out tests (Gao et al.,

1988) and fiber stress relaxation after unloading (Marshall and Oliver, 1987). More

rigorous analyses are still evolving (e.g., Hsueh, 1993; Lu and Mai, 1994), and

further details are discussed in Chapter 4.

3.2.7. Comparison of microcomposite tests and experimental data

It has been noted in a round robin test of microcomposites that there are large

variations in test results for an apparently identical fiber and matrix system between

13 different laboratories and testing methods (Pitkethly et al., 1993). Table 3.1 and

Fig 3.15 summarize the IFSS values of Courtaulds XA (untreated and standard

surface treated) carbon fibers embedded in an MY 750 epoxy resin. It is noted that

the difference in the average ISS values between testing methods, inclusive of the

fiber fragmentation test, fiber pull-out test, microdebond test and microindentation

test, are as high as a factor of 2.7. The most significant variation in ISS is obtained in

the fiber pull-out /microdebond tests for the fibers with prior surface treatments, and

the microindentation test shows the least variation.

There are a number of factors contributing to this discrepancy, such as a lack of

standardization in specimen preparation, the loading method, the measurement and

data reduction methods. Details of major contributors to the large data scatter are

summarized for each testing method in the following:

(i) Fiber pull-out test: measurement of embedded length, loading rate, alignment of

fiber with loading axis, accuracy of measurements of fiber diameter.

(ii) Microdebond test: size and shape (e.g. symmetry) of the droplet, shape of the

meniscus produced with the fiber, variations in the concentration of hardener within

the droplet, shape and size of the specimen holder (i.e. microvice).

(iii) Fragmentation test: level of preload applied to the fiber during the curing

process, loading method (e.g. continuous loading by electronic device versus