Page 81 - Engineered Interfaces in Fiber Reinforced Composites

P. 81

64 Engineered interfaces in jiber reinforced composites

SDR= L/ t 4

SDR=L/t=4

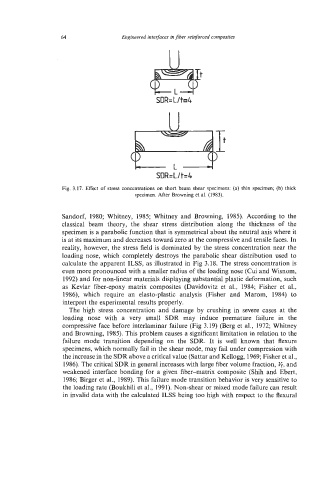

Fig. 3.17. Effect of stress concentrations on short beam shear specimens: (a) thin specimen; (b) thick

specimen. After Browning et al. (1983).

Sandorf, 1980; Whitney, 1985; Whitney and Browning, 1985). According to the

classical beam theory, the shear stress distribution along the thickness of the

specimen is a parabolic function that is symmetrical about the neutral axis where it

is at its maximum and decreases toward zero at the compressive and tensile faces. In

reality, however, the stress field is dominated by the stress concentration near the

loading nose, which completely destroys the parabolic shear distribution used to

calculate the apparent ILSS, as illustrated in Fig 3.18. The stress concentration is

even more pronounced with a smaller radius of the loading nose (Cui and Wisnom,

1992) and for non-linear materials displaying substantial plastic deformation, such

as Kevlar fiber-epoxy matrix composites (Davidovitz et al., 1984; Fisher et al.,

1986), which require an elasto-plastic analysis (Fisher and Marom, 1984) to

interpret the experimental results properly.

The high stress concentration and damage by crushing in severe cases at the

loading nose with a very small SDR may induce premature failure in the

compressive face before interlaminar failure (Fig 3.19) (Berg et al., 1972; Whitney

and Browning, 1985). This problem causes a significant limitation in relation to the

failure mode transition depending on the SDR. It is well known that flexure

specimens, which normally fail in the shear mode, may fail under compression with

the increase in the SDR above a critical value (Sattar and Kellogg, 1969; Fisher et al.,

1986). The critical SDR in general increases with large fiber volume fraction, 6, and

weakened interface bonding for a given fiber-matrix composite (Shih and Ebert,

1986; Birger et al., 1989). This failure mode transition behavior is very sensitive to

the loading rate (Boukhili et al., 1991). Non-shear or mixed mode failure can result

in invalid data with the calculated ILSS being too high with respect to the flexural