Page 80 - Engineered Interfaces in Fiber Reinforced Composites

P. 80

Chapter 3. Measurements of interfacelinterlamimar properties 63

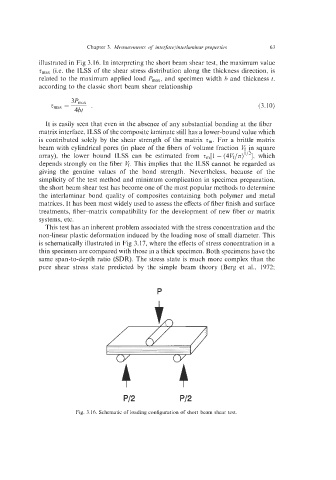

illustrated in Fig 3.16. In interpreting the short beam shear test, the maximum value

T~~~ (Le. the ILSS of the shear stress distribution along the thickness direction, is

related to the maximum applied load Pmax, and specimen width b and thickness t,

according to the classic short beam shear relationship

3Pmax

Tmax = - (3.10)

4bt

It is easily seen that even in the absence of any substantial bonding at the fiber-

matrix interface, ILSS of the composite laminate still has a lower-bound value which

is contributed solely by the shear strength of the matrix 7,. For a brittle matrix

beam with cylindrical pores (in place of the fibers of volume fraction vf in square

array), the lower bound ILSS can be estimated from zm[l - (4vf/~)~’~], which

depends strongly on the fiber vf. This implies that the ILSS cannot be regarded as

giving the genuine values of the bond strength. Nevertheless, because of the

simplicity of the test method and minimum complication in specimen preparation,

the short beam shear test has become one of the most popular methods to determine

the interlaminar bond quality of composites containing both polymer and metal

matrices. It has been most widely used to assess the effects of fiber finish and surface

treatments, fiber-matrix compatibility for the development of new fiber or matrix

systems, etc.

This test has an inherent problem associated with the stress concentration and the

non-linear plastic deformation induced by the loading nose of small diameter. This

is schematically illustrated in Fig 3.17, where the effects of stress concentration in a

thin specimen are compared with those in a thick specimen. Both specimens have the

same span-to-depth ratio (SDR). The stress state is much more complex than the

pure shear stress state predicted by the simple beam theory (Berg et al., 1972;

P

p/2 p/2

Fig. 3.16. Schematic of loading configuration of short beam shear test.