Page 281 - Engineering Plastics Handbook

P. 281

Liquid Crystal Polymer (LCP) 243

aromatic dicarboxylic acids [such as TPA, isophthalic acid (IPA), and

2,6-dicarboxynaphthalene (NDA)].

2. Acidolysis-type polycondensation reaction using aromatic hydroxyl

compounds (such as HBA, HNA, and DHB), aromatic dicarboxylic

acids (TPA and/or IPA), and acetic anhydride.

3. Acidolysis-type polycondensation reaction using acetyl derivative of

HBA and PET or PET oligomers.

® ®

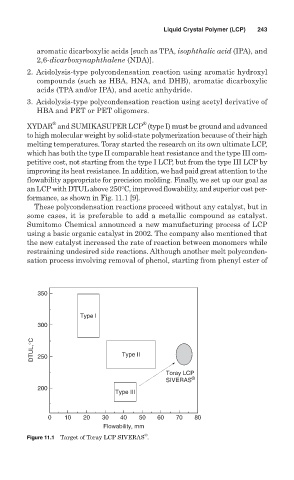

XYDAR and SUMIKASUPER LCP (type I) must be ground and advanced

to high molecular weight by solid-state polymerization because of their high

melting temperatures. Toray started the research on its own ultimate LCP,

which has both the type II comparable heat resistance and the type III com-

petitive cost, not starting from the type I LCP, but from the type III LCP by

improving its heat resistance. In addition, we had paid great attention to the

flowability appropriate for precision molding. Finally, we set up our goal as

an LCPwith DTULabove 250°C, improved flowability, and superior cost per-

formance, as shown in Fig. 11.1 [9].

These polycondensation reactions proceed without any catalyst, but in

some cases, it is preferable to add a metallic compound as catalyst.

Sumitomo Chemical announced a new manufacturing process of LCP

using a basic organic catalyst in 2002. The company also mentioned that

the new catalyst increased the rate of reaction between monomers while

restraining undesired side reactions. Although another melt polyconden-

sation process involving removal of phenol, starting from phenyl ester of

350

Type I

300

DTUL,°C 250 Type II

Toray LCP

SIVERAS ®

200

Type III

0 10 20 30 40 50 60 70 80

Flowability, mm

®

Figure 11.1 Target of Toray LCP SIVERAS .