Page 282 - Engineering Plastics Handbook

P. 282

244 Engineering Plastics

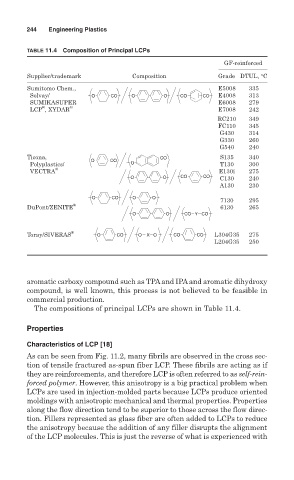

TABLE 11.4 Composition of Principal LCPs

GF-reinforced

Supplier/trademark Composition Grade DTUL, °C

Sumitomo Chem., E5008 335

Solvay/ O CO O O CO CO E4008 313

SUMIKASUPER E6008 279

®

LCP , XYDAR ® E7008 242

RC210 349

FC110 345

G430 314

G330 260

G540 240

Ticona, O CO CO S135 340

Polyplastics/ O T130 300

VECTRA ® E130i 275

O O CO CO C130 240

A130 230

O CO O O

7130 295

DuPont/ZENITE ® 6130 265

O O CO Y CO

Toray/SIVERAS ® O CO O X O CO CO L304G35 275

L204G35 250

aromatic carboxy compound such as TPAand IPAand aromatic dihydroxy

compound, is well known, this process is not believed to be feasible in

commercial production.

The compositions of principal LCPs are shown in Table 11.4.

Properties

Characteristics of LCP [18]

As can be seen from Fig. 11.2, many fibrils are observed in the cross sec-

tion of tensile fractured as-spun fiber LCP. These fibrils are acting as if

they are reinforcements, and therefore LCP is often referred to as self-rein-

forced polymer. However, this anisotropy is a big practical problem when

LCPs are used in injection-molded parts because LCPs produce oriented

moldings with anisotropic mechanical and thermal properties. Properties

along the flow direction tend to be superior to those across the flow direc-

tion. Fillers represented as glass fiber are often added to LCPs to reduce

the anisotropy because the addition of any filler disrupts the alignment

of the LCP molecules. This is just the reverse of what is experienced with