Page 283 - Engineering Plastics Handbook

P. 283

Liquid Crystal Polymer (LCP) 245

Figure 11.2 Typical SEM image

of tensile fractured as-spun fiber

of LCP.

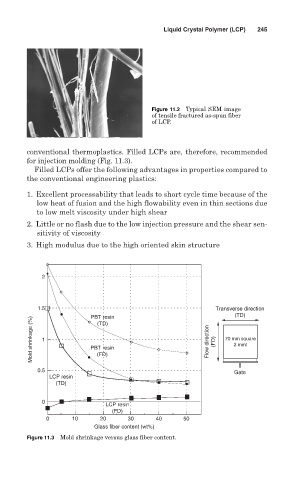

conventional thermoplastics. Filled LCPs are, therefore, recommended

for injection molding (Fig. 11.3).

Filled LCPs offer the following advantages in properties compared to

the conventional engineering plastics:

1. Excellent processability that leads to short cycle time because of the

low heat of fusion and the high flowability even in thin sections due

to low melt viscosity under high shear

2. Little or no flash due to the low injection pressure and the shear sen-

sitivity of viscosity

3. High modulus due to the high oriented skin structure

2

1.5 PBT resin Transverse direction

(TD)

Mold shrinkage (%) 1 PBT resin Flow direction (FD) 70 mm square

(TD)

2 mmt

(FD)

0.5 Gate

LCP resin

(TD)

0

LCP resin

(FD)

0 10 20 30 40 50

Glass fiber content (wt%)

Figure 11.3 Mold shrinkage versus glass fiber content.