Page 158 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 158

Funda1nentals of Part Modeling Engineering Design with SOLIDWORKS 2018

' I/

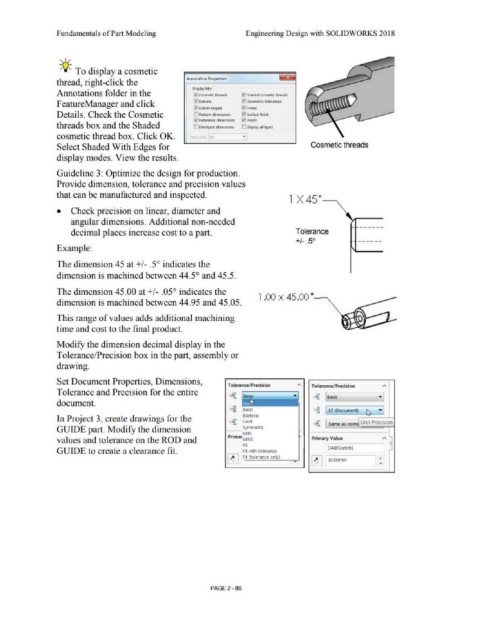

;Q;: To display a cosmetic

Annotation Properties

thread, right-click the

Display filter

Annotations folder in the 0 Cosmetic threads 10 Shaded cosmetic threads

F eatureManager and click l:{!Datums 10 Geometric tolerances

.t.l Datum targets 0 Notes

Details. Check the Cosmetic ;::] Feature dimensions 10 Surface finish

,/ Reference dimensions 0 welds

threads box and the Shaded [J DimXpert dimensions [) Display all types

cosmetic thread box. Click OK. Text cale 1:1

Select Shaded With Edges for Cosmetic threads

display modes. View the results.

Guideline 3: Optimize the design for production.

Provide dimension, tolerance and precision values

that can be manufactured and inspected.

1 x 45°--..

• Check precision on linear, diameter and

angular dimensions. Additional non-needed

decimal places increase cost to a part. Tolerance

+/- _50

Example:

The dimension 45 at +/- .5° indicates the

dimension is machined between 44.5° and 45.5.

The dimension 45.00 at +/- .05° indicates the

1 .00 X 45.00 °~

dimension is machined between 44.95 and 45.05.

This range of values adds additional machining

time and cost to the final product.

Modify the dimension decimal display in the

Tolerance/Precision box in the part, assembly or

drawing.

Set Document Properties, Dimensions, ,..

Tolerance/Precision Tolerance/Precision

Tolerance and Precision for the entire •.01 •,01

1.50

-.01 150 [ Basic ·I

... 01

document.

·"

•••

X.ICXX Basic X.XIX ·I

·" ••• [ .12 (Document) ~

In Project 3, create drawings for the .,. Bilateral

•,.X:C

1.SO Limit !SO Unit Precision

•.ICX -.xx Same as nomi

GUIDE part. Modify the dimension Symmetric

MIN ,.. -

values and tolerance on the ROD and Primar MAX Primary Value

Fit D4@Sketchl 0

GUIDE to create a clearance fit. Fit with tolerance

~ ....

~ Fit (tolerance only) ..

10.00mm

PAGE 2-86