Page 268 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 268

Fundamentals of Assembly Modeling Engineering Design with SOLIDWORKS® 2018

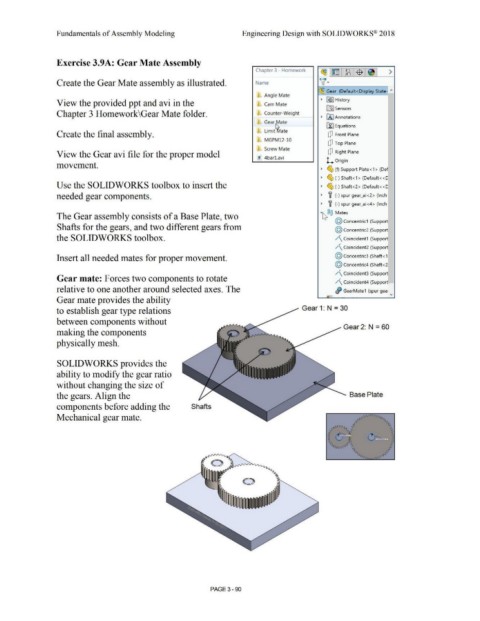

Exercise 3.9A: Gear Mate Assembly

Chapter 3 - Homework

~l~ l~:$ 1~1 >

Create the Gear Mate assembly as illustrated. Name v·

~ Gear (Default <Display State- "'

Angle Mate

View the provided ppt and avi in the Carn Mate • FE>] History

~ Sensors

Chapter 3 Homework\Gear Mate folder. Counter-Weight

• IA] Annotations

Gear ~ate

[fJ Equations

Create the final assembly. Limit 1t1ate [jJ Front Plane

MGPM12-10

[jJ Top Plane

Screw Mate

View the Gear avi file for the proper model [jJ Right Plane

~ 4barl.avi

L. Origin

movement.

• ~ (f) Support Plate<1 > (Def

• ~ (-) Shaft<1 > (Default < <C

Use the SOLIDWORKS toolbox to insert the • ~ (-) Shaft<2> (Default<<[

needed gear components. • f (-) spur gear_ai<2> (Inch

• f (-) spur gear_ai<4> (Inch

The Gear assembly consists of a Base Plate, two ·~®@ Mates

@ concentric1 (Support

Shafts for the gears, and two different gears from @ concentric2 (Support

the SOLIDWORKS toolbox. /\ Coincident 1 (Support

/\ Coincident2 (Support

Insert all needed mates for proper movement. @ concentric3 (Shaft<1

@ concentric4 (Shaft<2

/\ Coincident3 (Support

Gear mate: Forces two components to rotate

/\ Coincident4 (Support

relative to one another around selected axes. The - Ji GearMate1 (spur gea

Gear mate provides the ability "

to establish gear type relations Gear 1: N = 30

between components without

Gear 2: N = 60

making the components

physically mesh.

SOLIDWORKS provides the

ability to modify the gear ratio

without changing the size of

the gears. Align the Base Plate

components before adding the Shafts

Mechanical gear mate.

PAGE3 - 90