Page 266 - Subyek Computer Aided Design - [David Planchard] Engineering Design with SOLIDWORKS

P. 266

Fundamentals of Assembly Modeling Engineering Design with SOLIDWORKS® 2018

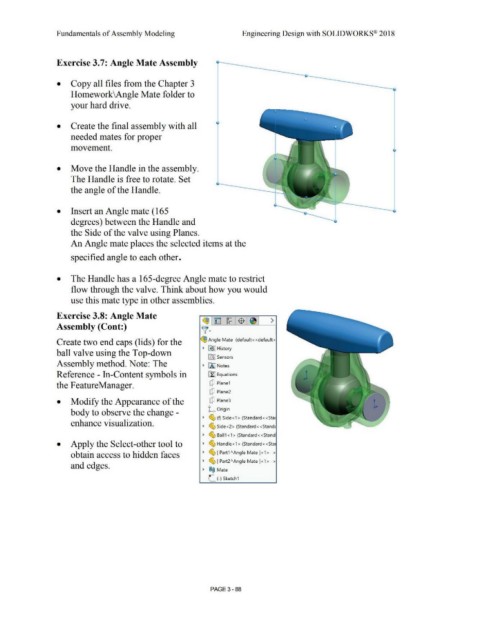

Exercise 3.7: Angle Mate Assembly

• Copy all files from the Chapter 3

Homework\Angle Mate folder to

your hard drive.

• Create the final assembly with all

needed mates for proper

movement.

• Move the Handle in the assembly.

The Handle is free to rotate. Set

the angle of the Handle.

• Insert an Angle mate (165

degrees) between the Handle and

the Side of the valve using Planes.

An Angle mate places the selected items at the

specified angle to each other.

• The Handle has a 165-degree Angle mate to restrict

flow through the valve. Think about how you would

use this mate type in other assemblies.

Exercise 3.8: Angle Mate ~1~1~1$ :~1 >

Assembly (Cont:) v-

Create two end caps (lids) for the ~ Angle Mate (default< <default>

> H£> I History

ball valve using the Top-down

lfrl Sensors

Assembly method. Note: The > fAI Notes

Reference - In-Content symbols in ~ Equations

the F eatureManager. dJ Plane1

dJ Plane2

• Modify the Appearance of the dJ Plane3

k Origin

body to observe the change -

~ ~ (f) Side<1> (Standard<<Sta1

enhance visualization.

> (9, Side<2> (Standard<<Standc

> (9, Ball1<1> (Standard<<Stand

• Apply the Select-other tool to > ~ Handle<1> (Standard<<Sta1

obtain access to hidden faces > ~ [ Part1 AAngle Mate ]<1 > - >

> ~ [ Part2" Angle Mate ]< 1> ->

and edges.

.-

~ ®@ Mate

L (-) Sketch1

PAGE 3- 88