Page 177 - Enhanced Oil Recovery in Shale and Tight Reservoirs

P. 177

Water injection 161

incremental improvement in oil production attributable to water injection

(Sorensen and Hamling, 2016).

7.3.3 Huff-n-puff water injection followed by huff-n-puff

CO 2 injection in Parshall Field

A Parshall Field well operated by EOG, the NDIC 16986, has been the

subject of both produced water and field gas injection testing. Water injec-

tion was conducted periodically from April 2012 to February 2014 in a

“waterflood pilot.” Nearly 439,000 barrels of water were injected before

the well was returned to production in March 2014. No obvious increase

in oil rate was observed (Sorensen and Hamling, 2016).

Starting in June 2014, EOG began injecting field gas mingled with pro-

duced water injection. Water was used to manage the effects of gas

mobility in the fracture system, or if needed, to build system pressure

with less gas volume. Through August 20, 2014, a total of 88.729 MMSCF

had been injected. Changes in fluid production rates were observed in two

offset wells, demonstrating that communication between wells can occur

rapidly. No data showed the test was successful (Sorensen and Hamling,

2016).

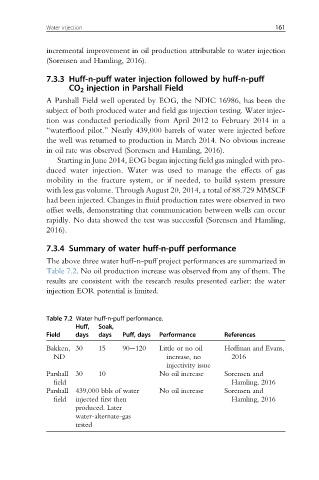

7.3.4 Summary of water huff-n-puff performance

The above three water huff-n-puff project performances are summarized in

Table 7.2. No oil production increase was observed from any of them. The

results are consistent with the research results presented earlier: the water

injection EOR potential is limited.

Table 7.2 Water huff-n-puff performance.

Huff, Soak,

Field days days Puff, days Performance References

Bakken, 30 15 90e120 Little or no oil Hoffman and Evans,

ND increase, no 2016

injectivity issue

Parshall 30 10 No oil increase Sorensen and

field Hamling, 2016

Parshall 439,000 bbls of water No oil increase Sorensen and

field injected first then Hamling, 2016

produced. Later

water-alternate-gas

tested