Page 372 - Enhanced Oil Recovery in Shale and Tight Reservoirs

P. 372

344 Enhanced Oil Recovery in Shale and Tight Reservoirs

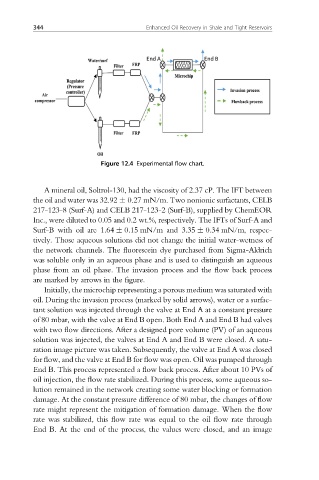

Figure 12.4 Experimental flow chart.

A mineral oil, Soltrol-130, had the viscosity of 2.37 cP. The IFT between

the oil and water was 32.92 0.27 mN/m. Two nonionic surfactants, CELB

217-123-8 (Surf-A) and CELB 217-123-2 (Surf-B), supplied by ChemEOR

Inc., were diluted to 0.05 and 0.2 wt.%, respectively. The IFTs of Surf-A and

Surf-B with oil are 1.64 0.15 mN/m and 3.35 0.34 mN/m, respec-

tively. Those aqueous solutions did not change the initial water-wetness of

the network channels. The fluorescein dye purchased from Sigma-Aldrich

was soluble only in an aqueous phase and is used to distinguish an aqueous

phase from an oil phase. The invasion process and the flow back process

are markedbyarrowsinthe figure.

Initially, the microchip representing a porous medium was saturated with

oil. During the invasion process (marked by solid arrows), water or a surfac-

tant solution was injected through the valve at End A at a constant pressure

of 80 mbar, with the valve at End B open. Both End A and End B had valves

with two flow directions. After a designed pore volume (PV) of an aqueous

solution was injected, the valves at End A and End B were closed. A satu-

ration image picture was taken. Subsequently, the valve at End A was closed

for flow, and the valve at End B for flow was open. Oil was pumped through

End B. This process represented a flow back process. After about 10 PVs of

oil injection, the flow rate stabilized. During this process, some aqueous so-

lution remained in the network creating some water blocking or formation

damage. At the constant pressure difference of 80 mbar, the changes of flow

rate might represent the mitigation of formation damage. When the flow

rate was stabilized, this flow rate was equal to the oil flow rate through

End B. At the end of the process, the values were closed, and an image