Page 84 - Enhanced Oil Recovery in Shale and Tight Reservoirs

P. 84

Asphaltene precipitation and deposition in a huff-n-puff process 71

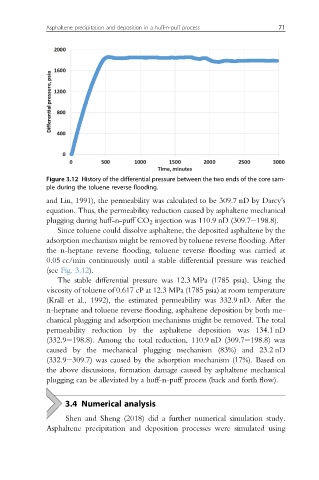

Figure 3.12 History of the differential pressure between the two ends of the core sam-

ple during the toluene reverse flooding.

and Liu, 1991), the permeability was calculated to be 309.7 nD by Darcy’s

equation. Thus, the permeability reduction caused by asphaltene mechanical

plugging during huff-n-puff CO 2 injection was 110.9 nD (309.7e198.8).

Since toluene could dissolve asphaltene, the deposited asphaltene by the

adsorption mechanism might be removed by toluene reverse flooding. After

the n-heptane reverse flooding, toluene reverse flooding was carried at

0.05 cc/min continuously until a stable differential pressure was reached

(see Fig. 3.12).

The stable differential pressure was 12.3 MPa (1785 psia). Using the

viscosity of toluene of 0.617 cP at 12.3 MPa (1785 psia) at room temperature

(Krall et al., 1992), the estimated permeability was 332.9 nD. After the

n-heptane and toluene reverse flooding, asphaltene deposition by both me-

chanical plugging and adsorption mechanisms might be removed. The total

permeability reduction by the asphaltene deposition was 134.1 nD

(332.9e198.8). Among the total reduction, 110.9 nD (309.7e198.8) was

caused by the mechanical plugging mechanism (83%) and 23.2 nD

(332.9e309.7) was caused by the adsorption mechanism (17%). Based on

the above discussions, formation damage caused by asphaltene mechanical

plugging can be alleviated by a huff-n-puff process (back and forth flow).

3.4 Numerical analysis

Shen and Sheng (2018) did a further numerical simulation study.

Asphaltene precipitation and deposition processes were simulated using