Page 133 - Entrophy Analysis in Thermal Engineering Systems

P. 133

126 Entropy Analysis in Thermal Engineering Systems

to produce roughly 30kW more power per unit molar flowrate of the fuel

than the original design. Given the relatively low temperature of the flue

gases (587.3K) at the inlet of the HRSG in the modified cycle, it would

rather be more practical to use an organic Rankine cycle (ORC) than

the steam cycle.

8.7 Organic Rankine cycle

The basic operating principles of an organic Rankine cycle (ORC) are

similar to the steam cycle. It consists of an evaporator, a turbine, a condenser,

and a pump. In some studies, an ORC with regeneration has also been

examined. ORCs have widely been recognized as a promising technology

to produce power from low-temperature heat. The working substance of

ORC is an organic fluid. Refrigerants like R1234yf are recommended fluids

for use in ORCs for low-to-moderate temperature ( 473K) heat sources

[4]. At relatively high heat source temperatures ( 573K), fluids with high

critical temperatures like toluene are employed [5]. Table 8.6 lists the prop-

erties of some working fluids employed in ORCs.

The common applications of ORCs include geothermal power plants,

biomass combined heat and power plants, integrated solar and ORC sys-

tems, industrial waste heat recovery, integrated internal combustion engine

and ORC systems [6]. The combined regenerative gas turbine and ORC has

also been reported. The flue gases temperature is relatively low at the exhaust

of regenerative gas turbines, e.g., 587.3K in Table 8.5. So, it would be

impractical to operate traditional combined gas/steam cycle with a low

exhaust temperature at high steam pressures mainly due to the significant

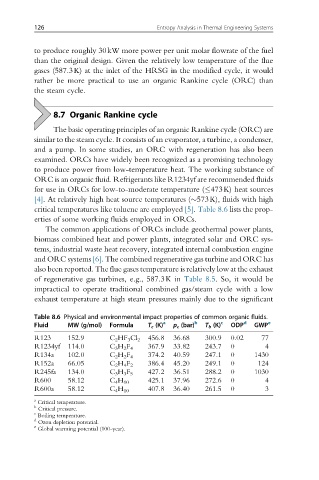

Table 8.6 Physical and environmental impact properties of common organic fluids.

Fluid MW (g/mol) Formula T c (K) a p c (bar) b T b (K) c ODP d GWP e

R123 152.9 C 2 HF 3 Cl 2 456.8 36.68 300.9 0.02 77

R1234yf 114.0 C 3 H 2 F 4 367.9 33.82 243.7 0 4

R134a 102.0 C 2 H 2 F 4 374.2 40.59 247.1 0 1430

R152a 66.05 C 2 H 4 F 2 386.4 45.20 249.1 0 124

R245fa 134.0 C 3 H 3 F 5 427.2 36.51 288.2 0 1030

R600 58.12 C 4 H 10 425.1 37.96 272.6 0 4

R600a 58.12 C 4 H 10 407.8 36.40 261.5 0 3

a

Critical temperature.

b

Critical pressure.

c

Boiling temperature.

d

Ozon depletion potential.

e

Global warming potential (100-year).