Page 37 - Estimators Piping Man Hour Manual

P. 37

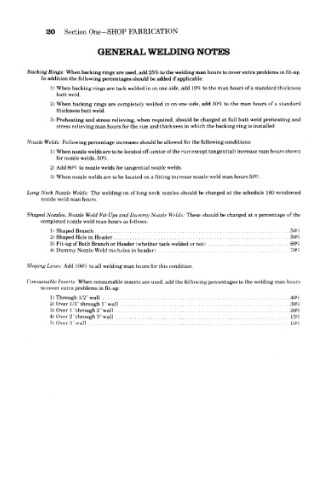

20 Section One-SHOP FABRICATION

GENERAL WELDING NOTES

Backing Rings: When backing rings are used, add 25% to the welding man hours to cover extra problems in fit-up.

In addition the following percentages should be added if applicable:

1) When backing rings are tack welded in on one side, add 10% to the man hours of a standard thickness

butt weld.

2) When backing rings are completely welded in on one side, add 30% to the man hours of a standard

thickness butt weld.

3) Preheating and stress relieving, when required, should be charged at full butt weld preheating and

stress relieving man hours for the size and thickness in which the backing ring is installed.

Nozzle Welds: Following percentage increases should be allowed for the following conditions:

1) When nozzle welds are to be located off-center of the runiexcept tangential) increase man hours shown

for nozzle welds, 50%.

2) Add 80% to nozzle welds for tangential nozzle welds.

3) When nozzle welds are to be located on a fitting increase nozzle weld man hours 50%.

Long Neck Nozzle Welds: The welding-on of long neck nozzles should be charged at the schedule 160 reinforced

nozzle weld man hours.

Shaped Nozzles, Nozzle Weld Fit-Ups and Dummy Nozzle Welds: These should be charged at a percentage of the

completed nozzle weld man hours as follows:

1) Shaped Branch 50%

2) Shaped Hole in Header , . .50%

.

3) Fit-up of Both Branch or Header (whether tack-welded or not) 60%

4) Dummy Nozzle Weld (no holes in header) 70%

Sloping Lines: Add 100% to all welding man hours for this condition.

Consumable Inserts: When consumable inserts are used, add the following percentages to the welding man hours

to cover extra problems in fit-up:

1) Through 1/2" wall 40%

2) Over 1/2" through 1" wall 30%

3! Over l"through 2" wall 20%

4) Over 2" through 3" wall 15*8

5) Over 3" wall 10%