Page 239 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 239

HEAT TRANSFER, INSULATION, AND FREEZE PROTECTION

HEAT TRANSFER, INSULATION, AND FREEZE PROTECTION 5.23

occur when the smaller cross section thickened and eventually closed, filling the pipe at

that point. As the ambient temperature dropped, the remainder of the water in the pipe froze

until the entire pipe was filled.

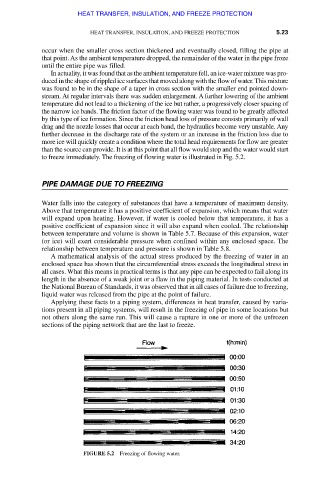

In actuality, it was found that as the ambient temperature fell, an ice-water mixture was pro-

duced in the shape of rippled ice surfaces that moved along with the flow of water. This mixture

was found to be in the shape of a taper in cross section with the smaller end pointed down-

stream. At regular intervals there was sudden enlargement. A further lowering of the ambient

temperature did not lead to a thickening of the ice but rather, a progressively closer spacing of

the narrow ice bands. The friction factor of the flowing water was found to be greatly affected

by this type of ice formation. Since the friction head loss of pressure consists primarily of wall

drag and the nozzle losses that occur at each band, the hydraulics become very unstable. Any

further decrease in the discharge rate of the system or an increase in the friction loss due to

more ice will quickly create a condition where the total head requirements for flow are greater

than the source can provide. It is at this point that all flow would stop and the water would start

to freeze immediately. The freezing of flowing water is illustrated in Fig. 5.2.

PIPE DAMAGE DUE TO FREEZING

Water falls into the category of substances that have a temperature of maximum density.

Above that temperature it has a positive coefficient of expansion, which means that water

will expand upon heating. However, if water is cooled below that temperature, it has a

positive coefficient of expansion since it will also expand when cooled. The relationship

between temperature and volume is shown in Table 5.7. Because of this expansion, water

(or ice) will exert considerable pressure when confined within any enclosed space. The

relationship between temperature and pressure is shown in Table 5.8.

A mathematical analysis of the actual stress produced by the freezing of water in an

enclosed space has shown that the circumferential stress exceeds the longitudinal stress in

all cases. What this means in practical terms is that any pipe can be expected to fail along its

length in the absence of a weak joint or a flaw in the piping material. In tests conducted at

the National Bureau of Standards, it was observed that in all cases of failure due to freezing,

liquid water was released from the pipe at the point of failure.

Applying these facts to a piping system, differences in heat transfer, caused by varia-

tions present in all piping systems, will result in the freezing of pipe in some locations but

not others along the same run. This will cause a rupture in one or more of the unfrozen

sections of the piping network that are the last to freeze.

FIGURE 5.2 Freezing of flowing water.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.