Page 217 - Failure Analysis Case Studies II

P. 217

202

2. EXPERIMENTAL DETAILS

2.1. ShaB system and strain gauging

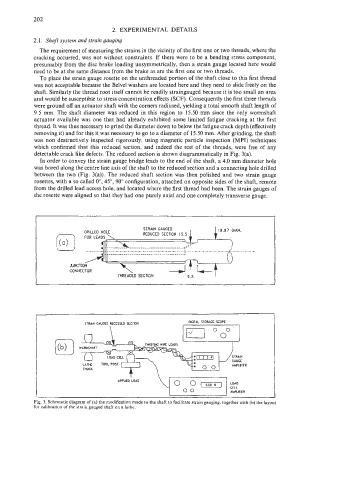

The requirement of measuring the strains in the vicinity of the first one or two threads, where the

cracking occurred, was not without constraints. If there were to be a bending stress component,

presumably from the disc brake loading unsymmetrically, then a strain gauge located here would

need to be at the same distance from the brake as are the first one or two threads.

To place the strain gauge rosette on the unthreaded portion of the shaft close to this first thread

was not acceptable because the Belvel washers are loated here and they need to slide freely on the

shaft. Similarly the thread root itself cannot be readily straingauged because it is too small an area

and would be susceptible to stress concentration effects (SCF). Consequently the first three threads

were ground off an actuator shaft with the corners radiused, yielding a total smooth shaft length of

9.5 mm. The shaft diameter was reduced in this region to 15.50 mm since the only wormshaft

actuator available was one that had already exhibited some limited fatigue cracking at the first

thread. It was thus necessary to grind the diameter down to below the fatigue crack depth (effectively

removing it) and for this it was necessary to go to a diameter of 15.50 mm. After grinding, the shaft

was non destructively inspected rigorously, using magnetic particle inspection (MPI) techniques

which confirmed that this reduced section, and indeed the rest of the threads, were free of any

detectable crack like defects. The reduced section is shown diagrammatically in Fig. 3(a).

In order to convey the strain gauge bridge leads to the end of the shaft, a 4.0 mm diameter hole

was bored along the centre line axis of the shaft to the reduced section and a connecting hole drilled

between the two (Fig. 3(a)). The reduced shaft section was then polished and two strain gauge

rosettes, with a so called O", 45", 90" configuration, attached on opposite sides of the shaft, remote

from the drilled lead access hole, and located where the first thread had been. The strain gauges of

the rosette were aligned so that they had one purely axial and one completely transverse gauge.

OICITAL STORAGE SCOPE

STRAN CAWD RECESKD SECTION

I

n \ I= "0"

Fig. 3. Schematic diagram of (a) the modification made to the shaft to facilitate strain gauging, together with (b) the layout

for calibration of the strain gauged shaft on a lathe.